Product Description

FAQ

Q1: Are you a trade company or a manufacturer?

A1: HangZhou Xihu (West Lake) Dis. Zhenjia Mold Accessories Factory is a professional manufacturer of plastic mold hardware accessories, undertake the design and processing of positioning block, slide core units, to provide customers with production services and technical support.

Q2: What to do if I have any other specifications?

A2:If you have any different requirements,just contact us and we will meet you.

Q3: If I need a sample for pretest, do you sale sample for this inquiry?

A3: Yes, we can sale sample for pretest. If you need this service, please contact us and we will give you a quotation.

Q4: Can you produce the products according to my own drawings?

A4: Yes, we can do OEM according to your requirem /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can hydraulic couplings handle both angular and axial misalignments simultaneously?

Yes, hydraulic couplings are designed to handle both angular and axial misalignments simultaneously. These couplings have inherent flexibility in their design, allowing them to accommodate various types of misalignments between the driving and driven shafts.

Angular misalignment occurs when the axes of the two shafts are not collinear, resulting in an angle between them. Axial misalignment, on the other hand, refers to the offset between the two shafts along their axis. Hydraulic couplings can compensate for these misalignments without sacrificing their ability to transmit torque efficiently.

The design of hydraulic couplings typically includes features such as flexible elements, torsional flexibility, or a fluid medium that allows the coupling to absorb and compensate for misalignments. When misalignment occurs, the flexible elements or fluid within the coupling act as a buffer, transmitting torque smoothly and reducing stress on the connected components.

By accommodating both angular and axial misalignments, hydraulic couplings offer several advantages in various applications:

- Reduced Wear: Hydraulic couplings’ ability to handle misalignments helps reduce wear and tear on the shafts, bearings, and other components, prolonging the life of the equipment.

- Smooth Operation: The ability to compensate for misalignments results in smoother operation and reduced vibrations, contributing to overall system performance and precision.

- Overload Protection: Hydraulic couplings can provide overload protection by allowing slippage when torque exceeds the coupling’s capacity, protecting the system from damage.

- Shock Absorption: In systems subject to shock loads or sudden changes in torque, hydraulic couplings can absorb and dampen these shocks, preventing damage to the equipment.

- Maintenance Reduction: By minimizing stress on the system components, hydraulic couplings can help reduce maintenance requirements and downtime.

It is important to note that the extent of misalignment accommodation may vary depending on the specific design and type of hydraulic coupling. Manufacturers provide guidelines and specifications for each coupling, including the maximum allowable misalignments.

Overall, hydraulic couplings’ ability to handle both angular and axial misalignments simultaneously makes them a versatile choice for various industrial applications where precision, efficiency, and reliable power transmission are essential.

What are some real-world examples of successful hydraulic coupling installations and their benefits?

Hydraulic couplings have been successfully implemented in various real-world applications, offering significant benefits in terms of performance, efficiency, and reliability. Here are some examples of successful hydraulic coupling installations and the advantages they provided:

- Construction Equipment: In the construction industry, hydraulic couplings are extensively used in excavators, loaders, bulldozers, and cranes. The flexibility and high torque transmission capability of hydraulic couplings ensure smooth and precise movements of heavy machinery, improving productivity and reducing wear on mechanical components. Additionally, the leak-free connections in hydraulic systems prevent fluid loss and environmental contamination.

- Industrial Manufacturing: In manufacturing plants, hydraulic couplings are commonly found in various equipment like hydraulic presses, injection molding machines, and metal forming machinery. The instant response and controllability of hydraulic systems, enabled by high-quality couplings, allow precise positioning and repeatable operations, ensuring consistent product quality and reducing material waste.

- Agricultural Machinery: Hydraulic couplings play a vital role in agricultural machinery, such as tractors, harvesters, and irrigation systems. The ability to handle varying loads and pressures in hydraulic couplings ensures efficient operation in different farming tasks. Moreover, the robustness and resistance to environmental factors contribute to the longevity and reliability of the agricultural equipment.

- Mobile Equipment: Mobile hydraulic applications, including waste collection trucks, fire trucks, and utility service vehicles, benefit from hydraulic couplings’ compact design and versatility. Hydraulic systems with the right couplings offer precise control, even in confined spaces, making them suitable for diverse mobile operations.

- Material Handling: Hydraulic couplings are integral to material handling equipment like forklifts, conveyor systems, and pallet stackers. The smooth acceleration and deceleration provided by hydraulic couplings improve safety and handling efficiency, allowing operators to maneuver heavy loads with ease.

- Offshore and Marine: In offshore and marine applications, hydraulic couplings are used in cranes, winches, and other systems. The hermetically sealed magnetic couplings, for instance, prevent fluid leakage in critical marine environments, reducing maintenance costs and minimizing the risk of contamination in sensitive marine ecosystems.

The benefits of these successful hydraulic coupling installations include:

- Improved Performance: Hydraulic couplings enable precise control and efficient power transmission, resulting in improved equipment performance and productivity.

- Energy Efficiency: Hydraulic couplings with reduced pressure losses and optimized fluid flow contribute to energy savings, making hydraulic systems more environmentally friendly and cost-effective.

- Enhanced Safety: The reliability and leak-free operation of hydraulic couplings increase operational safety, reducing the risk of accidents and equipment failures.

- Extended Equipment Lifespan: Properly selected and maintained hydraulic couplings contribute to the longevity of hydraulic systems, reducing downtime and maintenance costs.

- Environmental Protection: Hydraulic couplings, especially those with non-leak designs, help prevent fluid spills and reduce the impact of hydraulic systems on the environment.

These real-world examples illustrate the versatility and advantages of hydraulic couplings across different industries. The proper selection and installation of hydraulic couplings can significantly enhance the performance, efficiency, and reliability of various hydraulic systems, delivering long-term benefits for businesses and end-users alike.

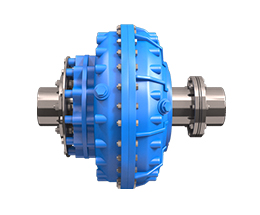

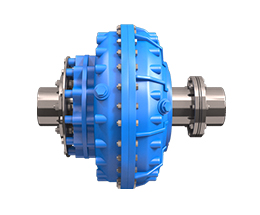

What is a hydraulic coupling, and how does it function in fluid power transmission?

A hydraulic coupling is a mechanical device used in fluid power systems to transmit power from one shaft to another, often at different angles or distances. It facilitates the transfer of hydraulic energy from a prime mover, such as an electric motor or an internal combustion engine, to various hydraulic components, such as pumps, actuators, and cylinders.

The main function of a hydraulic coupling is to transmit rotational motion and power while accommodating misalignments and torsional vibrations. It acts as a link between the driving and driven shafts, ensuring that the hydraulic system operates smoothly and efficiently.

Hydraulic couplings operate based on the principle of hydraulic fluid transmission. The coupling consists of two main parts, the input (driving) and output (driven) elements, both of which have specially designed vanes or blades. These vanes are submerged in hydraulic fluid.

When the input element rotates, it creates a flow of hydraulic fluid around the vanes, which in turn generates pressure on the output element. The pressure difference between the two elements causes the output element to start rotating, effectively transmitting power from the input shaft to the output shaft.

Hydraulic couplings are advantageous in various applications due to their ability to:

- Isolate Shock Loads: They can isolate and dampen shock loads and torsional vibrations, protecting sensitive components from sudden jolts and improving overall system performance.

- Accommodate Misalignment: Hydraulic couplings can accommodate misalignment between the input and output shafts, reducing wear and tear on the system and extending the lifespan of the components.

- Provide Overload Protection: They offer overload protection by slipping or disengaging when the torque exceeds a certain threshold, preventing damage to the system and its components.

- Start-Up Assistance: Hydraulic couplings can provide smooth start-up assistance, gradually transmitting power as the fluid builds up pressure, minimizing shock and stress during system startup.

- Reduce Noise and Vibration: By dampening vibrations and shock loads, hydraulic couplings contribute to quieter and smoother operation of fluid power systems.

Overall, hydraulic couplings play a critical role in fluid power transmission, ensuring efficient power transfer, protecting components from shocks and vibrations, and enhancing the overall performance and reliability of hydraulic systems in various industrial and mobile applications.

editor by CX 2024-05-07

China Hot selling Customized Factory 45deg Bsp Female 60deg Cone Elbow Hydraulic Hose Fittings Couplings

Product Description

| Model NO. | 22642-06-06 | Color | Silver/Yellow |

| Delivery Time | 20 Days | Origin | China ZheJiang |

| Trademark | Beiteer | Transport Package | Wooden Pallets/Box |

| Production Capacity | 10000Piece/day | Material | 20# Steel/45#Steel/Stainless steel |

Our Advantages

The factory specializes in the production and development of various types of hydraulic hose joints,transition joints and hose assembly of 1 of the large enterprises.At present,the company has a variety of hydraulic joints,hose assemblies products with excellent structure, advanced design and other characteristics,widely used in engineering,metallurgy,agriculture, machinery,oil fields,ships and other industries of hydraulic and fluid delivery systems.Our factory can customize products according to customers’ needs.

FAQ

1.Are you manufactory?

Yes,We have our own factory.

2.How about the samples?

We can send you samples with little and reasonable charge.

3.How about your quality?

You can try a small order and you will have your judgement.

4.What’s your payment term?

L/C, T/T

5.What’s the shipping port?

ZheJiang port

6.Does your factory accept customization?

Yes,we can make them according to your drawings.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do hydraulic couplings contribute to reducing vibrations and noise in hydraulic systems?

Hydraulic couplings play a crucial role in reducing vibrations and noise in hydraulic systems, providing several mechanisms that help dampen and absorb these unwanted effects. Here’s how hydraulic couplings contribute to vibration and noise reduction:

- Torsional Flexibility: Hydraulic couplings are designed with torsional flexibility, allowing them to twist and absorb torsional vibrations that may occur during operation. As the fluid flows through the coupling, it acts as a damping medium, attenuating vibrations and minimizing their transmission to the rest of the system.

- Vibration Isolation: The inherent flexibility of hydraulic couplings helps isolate vibrations between the driving and driven components of the hydraulic system. This isolation prevents vibrations from propagating through the system, reducing the overall vibration levels and promoting smoother operation.

- Shock Absorption: In systems subject to sudden changes in load or pressure, hydraulic couplings can act as shock absorbers. They cushion the impact of these shock loads, preventing them from reverberating through the system and causing noise or damage to sensitive components.

- Damping Characteristics: Hydraulic couplings, especially those utilizing a hydraulic fluid medium, exhibit excellent damping characteristics. The fluid dissipates energy by converting kinetic energy into heat energy, effectively reducing the system’s resonant vibrations and noise.

- Smooth Power Transmission: Hydraulic couplings provide smooth power transmission between the driving and driven elements. The absence of jerks or sudden changes in torque helps in minimizing vibrations and noise generation, leading to quieter operation.

- Compensation for Misalignments: Hydraulic couplings can compensate for certain misalignments between the shafts they connect. By accommodating misalignments, the couplings reduce the stress on the system components, mitigating vibrations that might arise from misalignment-induced forces.

- Elimination of Metal-to-Metal Contact: In certain couplings, the use of elastomeric or flexible elements eliminates direct metal-to-metal contact between the driving and driven shafts. This reduces transmission of vibrations and noise, resulting in a quieter system.

By incorporating these vibration and noise-reducing features, hydraulic couplings enhance the overall performance and longevity of hydraulic systems. They contribute to a more pleasant working environment by minimizing noise levels and reducing the risk of fatigue failure caused by excessive vibrations. Additionally, reduced vibrations help prevent premature wear and extend the lifespan of system components, ultimately leading to cost savings and improved efficiency in industrial applications.

How do hydraulic couplings compare to other coupling types, such as mechanical or magnetic couplings?

Hydraulic couplings, mechanical couplings, and magnetic couplings are three distinct types of couplings used in various applications to transmit power between shafts. Each type of coupling offers specific advantages and limitations, making them suitable for different scenarios. Here’s a comparison of hydraulic couplings with mechanical and magnetic couplings:

- Power Transmission:

- Hydraulic Couplings: Hydraulic couplings transmit power using hydraulic fluid to transfer torque between connected shafts. They are well-suited for applications with varying torque demands, as the fluid medium can accommodate fluctuations and dampen shock loads.

- Mechanical Couplings: Mechanical couplings directly connect the shafts through solid mechanical links, such as rigid couplings or flexible couplings (e.g., gear, jaw, or disc couplings). They efficiently transmit power without losses, making them suitable for high-torque applications.

- Magnetic Couplings: Magnetic couplings use magnetic fields to transfer torque between shafts. They offer non-contact power transmission, which eliminates the need for mechanical seals, making them suitable for applications requiring hermetic sealing, such as pumps handling hazardous fluids.

- Speed and Torque:

- Hydraulic Couplings: Hydraulic couplings can accommodate variations in speed and torque within their design limits. They offer good torque-to-inertia ratio, enabling smooth acceleration and deceleration in hydraulic systems.

- Mechanical Couplings: Mechanical couplings maintain precise shaft alignment and have high torque capacity. However, they may not handle speed variations as effectively as hydraulic couplings.

- Magnetic Couplings: Magnetic couplings are not suitable for high-torque applications, but they offer excellent speed control and precise torque transmission without direct contact between shafts.

- Maintenance and Wear:

- Hydraulic Couplings: Hydraulic couplings may require periodic maintenance, such as seal replacements, to ensure proper operation. They experience wear due to fluid flow and pressure.

- Mechanical Couplings: Mechanical couplings have mechanical wear and may require lubrication and maintenance to sustain optimal performance and prevent misalignment over time.

- Magnetic Couplings: Magnetic couplings have minimal wear and require less maintenance due to their non-contact nature. They are less prone to mechanical failures but may require magnetic field adjustments.

- Environmental Considerations:

- Hydraulic Couplings: Hydraulic couplings may require hydraulic fluid, which must be properly managed and maintained. They can be susceptible to fluid leakage if not adequately sealed.

- Mechanical Couplings: Mechanical couplings can generate friction and heat during operation, which may require cooling measures in high-speed applications.

- Magnetic Couplings: Magnetic couplings are hermetically sealed, preventing fluid leakage and offering environmental advantages in applications where containment is critical.

The selection of the most appropriate coupling type depends on the specific requirements of the application, including torque, speed, environmental factors, maintenance considerations, and cost. Each coupling type offers unique features that cater to diverse industrial needs, making them valuable components in numerous mechanical systems.

Are there specific pressure and temperature limits for different hydraulic coupling designs?

Yes, different hydraulic coupling designs have specific pressure and temperature limits, and these limits can vary based on the coupling type and construction materials. Here are some general considerations regarding pressure and temperature limits for common hydraulic coupling designs:

- Jaw Couplings: Jaw couplings typically have a pressure rating ranging from 1000 psi to 5000 psi (6.9 MPa to 34.5 MPa) and can handle temperatures from -20°C to 120°C (-4°F to 248°F). These couplings are suitable for various industrial applications with moderate pressure and temperature requirements.

- Disc Couplings: Disc couplings offer higher pressure and temperature capabilities compared to jaw couplings. Their pressure rating can range from 2000 psi to 6000 psi (13.8 MPa to 41.4 MPa), and they can handle temperatures between -50°C to 150°C (-58°F to 302°F). These couplings are commonly used in high-performance and precision equipment.

- Fluid Couplings: Fluid couplings are suitable for applications requiring smooth start-ups and shock absorption. Their pressure limits can range from 150 psi to 3000 psi (1.03 MPa to 20.7 MPa), and they can handle temperatures from -40°C to 150°C (-40°F to 302°F). These couplings are often used in heavy machinery, such as conveyors and crushers.

- Gear Couplings: Gear couplings have a higher pressure rating, typically ranging from 2500 psi to 8000 psi (17.2 MPa to 55.2 MPa), and can handle temperatures from -20°C to 150°C (-4°F to 302°F). These couplings are commonly used in heavy-duty industrial applications with high torque requirements.

- Oldham Couplings: Oldham couplings have pressure limits ranging from 500 psi to 3000 psi (3.4 MPa to 20.7 MPa) and can handle temperatures between -30°C to 100°C (-22°F to 212°F). They are suitable for applications where shafts are not in perfect alignment.

- Diaphragm Couplings: Diaphragm couplings offer high pressure and temperature capabilities. Their pressure rating can range from 3000 psi to 10000 psi (20.7 MPa to 68.9 MPa), and they can handle temperatures from -50°C to 200°C (-58°F to 392°F). These couplings are commonly used in high-speed and high-temperature applications like pumps and compressors.

- Beam Couplings: Beam couplings typically have a pressure rating ranging from 1000 psi to 4000 psi (6.9 MPa to 27.6 MPa) and can handle temperatures between -40°C to 150°C (-40°F to 302°F). They are commonly used in precision equipment and motion control applications.

It’s essential to consult the manufacturer’s specifications and guidelines for each specific hydraulic coupling design to ensure it is suitable for the intended application’s pressure and temperature requirements. Using a coupling within its specified limits ensures safe and reliable operation and maximizes the performance and lifespan of the hydraulic system.

editor by CX 2024-05-06

China manufacturer Hydraulic System Hydraulic Hose Crimping Fittings and Couplings

Product Description

| Material | Brass,Copper,Stainless steel,Plastic (according to customer’s requirement) |

| Package Way | Standars Carton+pallet or Customized like Blister all ok |

| LeadTime | 30 days as usual, it will base on the order QTY and delivery due to customer’s plan |

| Payment | T/T or L/C |

| MOQ: | 1000PCS |

| Transportation | By sea or By air |

| Equipment | Forging Machine, CNC machine,stamping machine, sand blasting machine etc |

| Customized | Customized are welcome |

| QC Inspection | 100% inspection before package and delivery |

| Factory Experience | More than 20 years manufacture and customized products experience |

| Certificate | ISO9001:2015, ROHS, SGS, Material Certification |

| Sample | Samples and Dimensions report will offer to customer for confirmati |

workshop

FAQ

1), Q: How can I get a sample?

A: Yes, if customer want, we will express couple pcs samples free for customer to check before we arrange batch producing, we would like to talk with customer to get your kindly advise .

2), Q: How Your Factory Control the Quality ?

A: We control the quality since Material arrive, we have workshop QC responsible for each producting line to check the product dimensions and other details during 1 by 1 producing process, inspection QC do spot check for each batch in everyday and package workers do 100% product appearance inspection 1 by 1 when they package the parts into the carton.

We trust quality need to control on the producing line not final step.

3), what’s machine you do for these machining parts?

A: we have high precision machining center to produce for small tolerance products and we also have some automatic CNC machine, CNC machine, stamping machine, automatic drill-hole machine and sandblasting maching etc, except the plating, we do whole producing process in own factory.

We are glad to receive your message, Welcome to contact us. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can hydraulic couplings be used in applications involving corrosive or aggressive fluids?

Yes, hydraulic couplings can be used in applications involving corrosive or aggressive fluids, but the choice of materials and design considerations is critical to ensure compatibility and long-term performance. Corrosive fluids, such as acids, alkalis, and certain chemicals, can pose significant challenges to hydraulic systems. Here are some key factors to consider when using hydraulic couplings in such applications:

- Material Selection: Choose hydraulic couplings made from materials that are resistant to the specific corrosive fluid being handled. Stainless steel, certain alloys, and corrosion-resistant coatings are common choices for couplings in corrosive environments.

- Sealing Solutions: Ensure that the couplings have effective sealing solutions to prevent fluid leakage. High-quality seals and gaskets that are compatible with the corrosive fluid are essential to maintain system integrity.

- Chemical Compatibility: Thoroughly assess the chemical compatibility between the hydraulic fluid and the coupling materials. Consider the fluid’s temperature, concentration, and potential reactions with the coupling components.

- Special Coatings: In some cases, using hydraulic couplings with specialized coatings or treatments can enhance their resistance to corrosion and aggressive fluids.

- Regular Inspection and Maintenance: Implement a stringent inspection and maintenance schedule to monitor the condition of the hydraulic couplings and detect any signs of corrosion or degradation. Promptly replace any damaged or worn couplings to prevent fluid leaks and system failure.

- Fluid Contamination: Corrosive fluids can lead to the formation of contaminants in the hydraulic system. Implement effective filtration and contamination control measures to prevent particle buildup and system damage.

- Operating Conditions: Consider the temperature, pressure, and flow conditions of the system, as these factors can impact the corrosion resistance of the couplings and the overall system performance.

While hydraulic couplings can be used in corrosive or aggressive fluid applications, it is essential to consult with coupling manufacturers or fluid system experts to ensure proper material selection and system design. They can provide guidance on selecting the most suitable hydraulic couplings and recommend additional measures to protect the system from the adverse effects of corrosive fluids.

By employing the right materials, adopting proper maintenance practices, and taking the necessary precautions, hydraulic couplings can effectively function in applications involving corrosive or aggressive fluids, providing reliable and safe fluid power transmission.

How do hydraulic couplings ensure efficient torque transmission and prevent fluid leaks?

Hydraulic couplings are designed with specific features to ensure efficient torque transmission and prevent fluid leaks, making them vital components in hydraulic systems. These features contribute to the overall performance and reliability of the hydraulic system. Here’s how hydraulic couplings achieve these goals:

- High-Quality Materials: Hydraulic couplings are manufactured using high-quality materials, such as steel, stainless steel, brass, or other durable alloys. These materials offer excellent strength and wear resistance, allowing the couplings to withstand high torque and pressure loads without deforming or leaking.

- Precision Machining: Hydraulic couplings undergo precise machining processes to achieve tight tolerances and smooth surfaces. This ensures proper alignment and mating of coupling components, minimizing energy losses and enhancing torque transmission efficiency.

- Sealing Mechanisms: Hydraulic couplings incorporate various sealing mechanisms to prevent fluid leaks. O-rings, seals, or face seals are common sealing methods used in hydraulic couplings. When the coupling components are connected, the seals create a secure barrier, preventing hydraulic fluid from escaping the system.

- Leak-Free Designs: Modern hydraulic couplings often feature leak-free designs that minimize the risk of fluid leakage during operation. These designs utilize advanced sealing technologies and tight tolerances to ensure a reliable and durable connection, even under high-pressure conditions.

- Threaded Connections: Many hydraulic couplings use threaded connections, such as NPT, BSP, JIC, or SAE threads, to create a secure and leak-resistant joint. Properly tightened threaded connections maintain the integrity of the hydraulic system, reducing the likelihood of leaks.

- Quick-Connect Couplings: Quick-connect hydraulic couplings are designed for rapid and easy connection and disconnection, often without the need for additional tools. These couplings use internal valves and seals to ensure a leak-free connection when engaged and prevent fluid leaks when disengaged.

- Hermetically Sealed Couplings: In specific applications, hermetically sealed hydraulic couplings use magnetic coupling technology to provide a non-contact, leak-free transmission of torque and power. These couplings have no physical contact points, making them suitable for critical environments or systems handling hazardous fluids.

The combination of these design features ensures that hydraulic couplings efficiently transmit torque from one component to another while maintaining a secure and reliable seal to prevent fluid leaks. This is particularly important in hydraulic systems, where fluid leakage can lead to reduced performance, increased maintenance, and potential safety hazards.

Proper selection, installation, and maintenance of hydraulic couplings are crucial to optimize their torque transmission capabilities and prevent fluid leaks. Regular inspections and replacement of worn-out seals or damaged couplings are essential to ensure the continued efficiency and safety of the hydraulic system.

In summary, hydraulic couplings play a crucial role in efficient torque transmission and fluid sealing in hydraulic systems. Their robust construction, precision engineering, and advanced sealing technologies contribute to the overall performance and reliability of hydraulic machinery and equipment.

How do you select the appropriate hydraulic coupling for specific fluid handling needs?

Selecting the right hydraulic coupling for specific fluid handling needs involves considering several critical factors to ensure optimal performance and reliability. Here’s a step-by-step guide to help you make an informed choice:

- Fluid Type: Identify the type of fluid that the coupling will handle. Different fluids have varying viscosities and chemical properties, which can impact the compatibility and material selection for the coupling.

- Operating Pressure and Temperature: Determine the maximum operating pressure and temperature that the coupling will experience. Ensure that the selected coupling is rated to handle the expected pressure and temperature levels without failure or deformation.

- Torque Requirements: Calculate the required torque capacity based on the power transmission needs of your system. Choose a coupling that can handle the anticipated torque while considering safety factors.

- Misalignment Tolerance: Evaluate the potential misalignments that may occur between the shafts in your system. Choose a coupling that offers sufficient misalignment tolerance to accommodate these variations without imposing excessive stress on the equipment.

- Vibration and Shock: Consider the level of vibration and shock the coupling will experience during operation. Select a coupling that can dampen vibrations and absorb shocks to protect the system components and ensure stable performance.

- Installation and Maintenance: Assess the ease of installation and maintenance requirements of the coupling. A well-designed coupling should be easy to install, inspect, and maintain, reducing downtime and maintenance costs.

- Environmental Factors: Take into account the environmental conditions in which the coupling will operate. Factors such as exposure to moisture, chemicals, dust, or extreme temperatures may affect the choice of coupling materials and coatings.

- Space Constraints: Consider the available space for installing the coupling. Some applications may have limited space, necessitating the use of compact or low-profile couplings.

- Coupling Type: Based on the above considerations, choose the most suitable coupling type for your specific fluid handling needs. Consider options such as jaw couplings, disc couplings, fluid couplings, gear couplings, or other specialized couplings based on your application requirements.

It’s essential to consult with coupling manufacturers or industry experts if you have specific or challenging application requirements. They can provide valuable insights and recommendations to ensure you select the right hydraulic coupling that meets your fluid handling needs and maximizes the efficiency and reliability of your system.

editor by CX 2024-05-02

China wholesaler Smooth Cover Hydraulic Oil Rubber Hose Sanyeflex Manufacturer High Quality Factory Price R1 R2 4sh 4sp Hot Sale Hoses Fittings Couplings

Product Description

SANYEFLEX Reliable Hydraulic Hose Manufacturer

Product Description

SAE 100R2 AT/DIN EN 853 2SN

INNER TUBE: oil-resistant synthetic rubber REINFORCEMENT: two high-10sile steel wire braid

COVER: abrasion and weather-resistant synthetic rubber

TEMPERATURE RANGE: -4ºC to +100ºC

Product Parameters

| DN | HOSE ID | Wire OD | Hose OD | Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | |||

| Inch | mm | mm | mm | MPa | Psi | MPa | Psi | Inch | mm | |

| 6 | 1/4 | 6.4 | 12.7 | 17.5 | 40.0 | 5800 | 160.0 | 22840 | 100 | 0.42 |

| 8 | 5/16 | 7.9 | 14.3 | 19.1 | 36.0 | 5250 | 140.0 | 20000 | 114 | 0.51 |

| 10 | 3/8 | 9.5 | 16.7 | 21.4 | 33.1 | 4800 | 132.0 | 18840 | 127 | 0.60 |

| 13 | 1/2 | 12.7 | 19.8 | 24.6 | 27.6 | 4000 | 110.0 | 15720 | 178 | 0.74 |

| 16 | 5/8 | 15.9 | 23.0 | 27.8 | 25.0 | 3630 | 100.0 | 14280 | 200 | 0.86 |

| 19 | 3/4 | 19.0 | 27.0 | 31.8 | 21.5 | 3120 | 85.0 | 12280 | 240 | 1.04 |

| 25 | 1 | 25.4 | 34.9 | 39.7 | 16.5 | 2400 | 65.0 | 9420 | 300 | 1.42 |

| 32 | 1-1/4 | 31.8 | 44.5 | 50.8 | 12.5 | 1820 | 50.0 | 7140 | 419 | 2.23 |

| 38 | 1-1/2 | 38.1 | 50.8 | 57.2 | 9.0 | 1310 | 36.0 | 5140 | 500 | 2.74 |

| 51 | 2 | 50.8 | 63.5 | 69.9 | 8.0 | 1160 | 32.0 | 4560 | 630 | 3.50 |

Wrapped Surface Hydraulic Hose Smooth Surface Hydraulic Hose

Application

Company Profile

ZheJiang CHINAMFG Fluid Technology Co., Ltd. is a China-US cooperative enterprise. SANYEFLEX has strong financial strength and technical strengths. Our factory occupies a total area of 110,000 square meters, with a plant area of 70,000 square CHINAMFG and a total investment of 65 million yuan. Our company has been deeply involved in the hydraulic hose industry for nearly 20 years. We have 2 technical research and development teams, and more than 40 on-the-job engineers are respectively dedicated to technical research in the field of hydraulic fluids and the development of refrigeration systems.

Our company specializes in the production of mid-high-end hydraulic hose series products, such as steel wire braided hose (American standard, German standard), steel wire spiral hose (American standard, German standard), metal hose, air pipe, and joints, and other products. With excellent product quality, perfect after-sales service, and reasonable prices, we gradually increase the market share of our products. Our products are widely used in mining, metallurgy, petroleum, construction machinery, and chemical industry, and are exported to more than 30 countries and regions such as the United Kingdom, the United States, Germany, South America, and Russia. The company adheres to the core values of “integrity-based, customer first”. Unswervingly promote the development concept of “leading by originality, developing talents, rooting in leanness, and bravely climbing the peak”. Carry out technical R&D and manufacturing closely around customer needs, provide first-class services to a broad audience, and strive to become an industry leader.

Factory tour

Packaging & Shipping

Why Choose SANYEFLEX?

- Specialized in hydraulic hose production research and development for 20 years, has rich experience and technology.

- Imported raw materials directly from the United States, Japan, and South Korea.

- Automatic mixer workshop.

- Using an intelligent production line fully automated transfer process.

- Each hose will pass strict inspection before delivery.

- Reliable product quality and high safety performance, reducing the cost of the enterprise.

FAQ

Q1:Can you do OEM?

A: Yes, we can do OEM products. Welcome!

Q2: Are you a factory or trading company?

A: Factory! We are a 100% manufacturer, and we have 20 years of experience in hydraulic rubber hose production. Welcome to visit our factory.

Q3: Is a free sample available?

A: Yes, free samples are available, customers only pay the freight cost.

Q4: How about your delivery time?

A: Within 20 days after you do the payment.

Q5: What are your terms of packing?

A: Generally in rolls well wrapped with colorful poly stripes or as your requirement.

Q6: What are your terms of payment?

A: Payment= 1000 USD, 30% T/T in advance, balance before shipment.

For more detailed product types information, please feel free to contact us!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do hydraulic couplings contribute to reducing vibrations and noise in hydraulic systems?

Hydraulic couplings play a crucial role in reducing vibrations and noise in hydraulic systems, providing several mechanisms that help dampen and absorb these unwanted effects. Here’s how hydraulic couplings contribute to vibration and noise reduction:

- Torsional Flexibility: Hydraulic couplings are designed with torsional flexibility, allowing them to twist and absorb torsional vibrations that may occur during operation. As the fluid flows through the coupling, it acts as a damping medium, attenuating vibrations and minimizing their transmission to the rest of the system.

- Vibration Isolation: The inherent flexibility of hydraulic couplings helps isolate vibrations between the driving and driven components of the hydraulic system. This isolation prevents vibrations from propagating through the system, reducing the overall vibration levels and promoting smoother operation.

- Shock Absorption: In systems subject to sudden changes in load or pressure, hydraulic couplings can act as shock absorbers. They cushion the impact of these shock loads, preventing them from reverberating through the system and causing noise or damage to sensitive components.

- Damping Characteristics: Hydraulic couplings, especially those utilizing a hydraulic fluid medium, exhibit excellent damping characteristics. The fluid dissipates energy by converting kinetic energy into heat energy, effectively reducing the system’s resonant vibrations and noise.

- Smooth Power Transmission: Hydraulic couplings provide smooth power transmission between the driving and driven elements. The absence of jerks or sudden changes in torque helps in minimizing vibrations and noise generation, leading to quieter operation.

- Compensation for Misalignments: Hydraulic couplings can compensate for certain misalignments between the shafts they connect. By accommodating misalignments, the couplings reduce the stress on the system components, mitigating vibrations that might arise from misalignment-induced forces.

- Elimination of Metal-to-Metal Contact: In certain couplings, the use of elastomeric or flexible elements eliminates direct metal-to-metal contact between the driving and driven shafts. This reduces transmission of vibrations and noise, resulting in a quieter system.

By incorporating these vibration and noise-reducing features, hydraulic couplings enhance the overall performance and longevity of hydraulic systems. They contribute to a more pleasant working environment by minimizing noise levels and reducing the risk of fatigue failure caused by excessive vibrations. Additionally, reduced vibrations help prevent premature wear and extend the lifespan of system components, ultimately leading to cost savings and improved efficiency in industrial applications.

Where can I find reputable suppliers or manufacturers of hydraulic couplings for my specific hydraulic system requirements?

Finding reputable suppliers or manufacturers of hydraulic couplings is essential to ensure the quality, performance, and compatibility of the couplings with your specific hydraulic system requirements. Here are some methods and sources to help you locate reliable hydraulic coupling suppliers:

- Online Directories and Marketplaces: Utilize online industrial directories and marketplaces that list hydraulic coupling manufacturers and suppliers. Websites like ThomasNet, Alibaba, and IndustryNet can provide comprehensive listings with company profiles and product offerings.

- Trade Shows and Exhibitions: Attend trade shows and exhibitions focused on fluid power and hydraulic components. These events offer an opportunity to meet suppliers in person, see product demonstrations, and discuss your specific requirements directly with the manufacturers.

- Industry Associations: Many industry associations, such as the International Fluid Power Society (IFPS) or the National Fluid Power Association (NFPA), maintain directories of member companies that offer hydraulic couplings and related products. These associations often have strict membership criteria, which can serve as a marker of reputable companies.

- Online Search Engines: Conduct a targeted search using online search engines. Use specific keywords related to your hydraulic system requirements, such as “high-pressure hydraulic couplings” or “quick-connect hydraulic couplings,” along with your location to find local suppliers.

- Manufacturer Websites: Visit the websites of well-known hydraulic coupling manufacturers. Reputable manufacturers often provide detailed product information, specifications, and contact details, making it easier to assess their suitability for your requirements.

- Customer Reviews and Testimonials: Look for customer reviews and testimonials to gauge the reputation and customer satisfaction of potential hydraulic coupling suppliers. Positive feedback from other customers can be an indicator of reliable and reputable manufacturers.

When evaluating hydraulic coupling suppliers, consider the following factors to ensure they meet your specific requirements:

- Product Range: Check if the supplier offers a diverse range of hydraulic couplings, including the types, sizes, and configurations that match your needs.

- Quality Assurance: Inquire about the supplier’s quality control processes and certifications to ensure their hydraulic couplings meet industry standards and regulatory requirements.

- Customization Options: If your hydraulic system requires specialized couplings, confirm if the supplier can provide customization options to meet your unique specifications.

- Technical Support: Assess the supplier’s technical expertise and support capabilities to assist with product selection, installation, and troubleshooting.

- Pricing and Delivery: Obtain competitive pricing and inquire about delivery lead times to ensure the supplier can meet your budget and project timelines.

- After-Sales Service: Inquire about the supplier’s after-sales service, warranty policies, and availability of spare parts to ensure long-term support for your hydraulic couplings.

By conducting thorough research and due diligence, you can find reputable suppliers or manufacturers of hydraulic couplings that align with your specific hydraulic system requirements. Working with reliable suppliers will help you obtain high-quality couplings that contribute to the efficient and reliable operation of your hydraulic system.

Are there specific pressure and temperature limits for different hydraulic coupling designs?

Yes, different hydraulic coupling designs have specific pressure and temperature limits, and these limits can vary based on the coupling type and construction materials. Here are some general considerations regarding pressure and temperature limits for common hydraulic coupling designs:

- Jaw Couplings: Jaw couplings typically have a pressure rating ranging from 1000 psi to 5000 psi (6.9 MPa to 34.5 MPa) and can handle temperatures from -20°C to 120°C (-4°F to 248°F). These couplings are suitable for various industrial applications with moderate pressure and temperature requirements.

- Disc Couplings: Disc couplings offer higher pressure and temperature capabilities compared to jaw couplings. Their pressure rating can range from 2000 psi to 6000 psi (13.8 MPa to 41.4 MPa), and they can handle temperatures between -50°C to 150°C (-58°F to 302°F). These couplings are commonly used in high-performance and precision equipment.

- Fluid Couplings: Fluid couplings are suitable for applications requiring smooth start-ups and shock absorption. Their pressure limits can range from 150 psi to 3000 psi (1.03 MPa to 20.7 MPa), and they can handle temperatures from -40°C to 150°C (-40°F to 302°F). These couplings are often used in heavy machinery, such as conveyors and crushers.

- Gear Couplings: Gear couplings have a higher pressure rating, typically ranging from 2500 psi to 8000 psi (17.2 MPa to 55.2 MPa), and can handle temperatures from -20°C to 150°C (-4°F to 302°F). These couplings are commonly used in heavy-duty industrial applications with high torque requirements.

- Oldham Couplings: Oldham couplings have pressure limits ranging from 500 psi to 3000 psi (3.4 MPa to 20.7 MPa) and can handle temperatures between -30°C to 100°C (-22°F to 212°F). They are suitable for applications where shafts are not in perfect alignment.

- Diaphragm Couplings: Diaphragm couplings offer high pressure and temperature capabilities. Their pressure rating can range from 3000 psi to 10000 psi (20.7 MPa to 68.9 MPa), and they can handle temperatures from -50°C to 200°C (-58°F to 392°F). These couplings are commonly used in high-speed and high-temperature applications like pumps and compressors.

- Beam Couplings: Beam couplings typically have a pressure rating ranging from 1000 psi to 4000 psi (6.9 MPa to 27.6 MPa) and can handle temperatures between -40°C to 150°C (-40°F to 302°F). They are commonly used in precision equipment and motion control applications.

It’s essential to consult the manufacturer’s specifications and guidelines for each specific hydraulic coupling design to ensure it is suitable for the intended application’s pressure and temperature requirements. Using a coupling within its specified limits ensures safe and reliable operation and maximizes the performance and lifespan of the hydraulic system.

editor by CX 2024-04-26

China manufacturer Smooth Cover Hydraulic Oil Rubber Hose Sanyeflex Manufacturer High Quality Factory Price R1 R2 4sh 4sp Hot Sale Hoses Fittings Couplings

Product Description

SANYEFLEX Reliable Hydraulic Hose Manufacturer

Product Description

SAE 100R2 AT/DIN EN 853 2SN

INNER TUBE: oil-resistant synthetic rubber REINFORCEMENT: two high-10sile steel wire braid

COVER: abrasion and weather-resistant synthetic rubber

TEMPERATURE RANGE: -4ºC to +100ºC

Product Parameters

| DN | HOSE ID | Wire OD | Hose OD | Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | |||

| Inch | mm | mm | mm | MPa | Psi | MPa | Psi | Inch | mm | |

| 6 | 1/4 | 6.4 | 12.7 | 17.5 | 40.0 | 5800 | 160.0 | 22840 | 100 | 0.42 |

| 8 | 5/16 | 7.9 | 14.3 | 19.1 | 36.0 | 5250 | 140.0 | 20000 | 114 | 0.51 |

| 10 | 3/8 | 9.5 | 16.7 | 21.4 | 33.1 | 4800 | 132.0 | 18840 | 127 | 0.60 |

| 13 | 1/2 | 12.7 | 19.8 | 24.6 | 27.6 | 4000 | 110.0 | 15720 | 178 | 0.74 |

| 16 | 5/8 | 15.9 | 23.0 | 27.8 | 25.0 | 3630 | 100.0 | 14280 | 200 | 0.86 |

| 19 | 3/4 | 19.0 | 27.0 | 31.8 | 21.5 | 3120 | 85.0 | 12280 | 240 | 1.04 |

| 25 | 1 | 25.4 | 34.9 | 39.7 | 16.5 | 2400 | 65.0 | 9420 | 300 | 1.42 |

| 32 | 1-1/4 | 31.8 | 44.5 | 50.8 | 12.5 | 1820 | 50.0 | 7140 | 419 | 2.23 |

| 38 | 1-1/2 | 38.1 | 50.8 | 57.2 | 9.0 | 1310 | 36.0 | 5140 | 500 | 2.74 |

| 51 | 2 | 50.8 | 63.5 | 69.9 | 8.0 | 1160 | 32.0 | 4560 | 630 | 3.50 |

Wrapped Surface Hydraulic Hose Smooth Surface Hydraulic Hose

Application

Company Profile

ZheJiang CHINAMFG Fluid Technology Co., Ltd. is a China-US cooperative enterprise. SANYEFLEX has strong financial strength and technical strengths. Our factory occupies a total area of 110,000 square meters, with a plant area of 70,000 square CHINAMFG and a total investment of 65 million yuan. Our company has been deeply involved in the hydraulic hose industry for nearly 20 years. We have 2 technical research and development teams, and more than 40 on-the-job engineers are respectively dedicated to technical research in the field of hydraulic fluids and the development of refrigeration systems.

Our company specializes in the production of mid-high-end hydraulic hose series products, such as steel wire braided hose (American standard, German standard), steel wire spiral hose (American standard, German standard), metal hose, air pipe, and joints, and other products. With excellent product quality, perfect after-sales service, and reasonable prices, we gradually increase the market share of our products. Our products are widely used in mining, metallurgy, petroleum, construction machinery, and chemical industry, and are exported to more than 30 countries and regions such as the United Kingdom, the United States, Germany, South America, and Russia. The company adheres to the core values of “integrity-based, customer first”. Unswervingly promote the development concept of “leading by originality, developing talents, rooting in leanness, and bravely climbing the peak”. Carry out technical R&D and manufacturing closely around customer needs, provide first-class services to a broad audience, and strive to become an industry leader.

Factory tour

Packaging & Shipping

Why Choose SANYEFLEX?

- Specialized in hydraulic hose production research and development for 20 years, has rich experience and technology.

- Imported raw materials directly from the United States, Japan, and South Korea.

- Automatic mixer workshop.

- Using an intelligent production line fully automated transfer process.

- Each hose will pass strict inspection before delivery.

- Reliable product quality and high safety performance, reducing the cost of the enterprise.

FAQ

Q1:Can you do OEM?

A: Yes, we can do OEM products. Welcome!

Q2: Are you a factory or trading company?

A: Factory! We are a 100% manufacturer, and we have 20 years of experience in hydraulic rubber hose production. Welcome to visit our factory.

Q3: Is a free sample available?

A: Yes, free samples are available, customers only pay the freight cost.

Q4: How about your delivery time?

A: Within 20 days after you do the payment.

Q5: What are your terms of packing?

A: Generally in rolls well wrapped with colorful poly stripes or as your requirement.

Q6: What are your terms of payment?

A: Payment= 1000 USD, 30% T/T in advance, balance before shipment.

For more detailed product types information, please feel free to contact us!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the maintenance requirements for hydraulic couplings to ensure optimal performance?

Maintaining hydraulic couplings is crucial to ensure their optimal performance and extend their service life. Regular maintenance helps identify potential issues early on and prevents costly breakdowns. Here are the essential maintenance requirements for hydraulic couplings:

- Inspection: Regularly inspect the hydraulic coupling for signs of wear, damage, or leaks. Check for any unusual noises, vibrations, or changes in performance during operation.

- Lubrication: Ensure proper lubrication of the coupling’s moving parts. Use the manufacturer-recommended lubricants and follow the specified intervals for re-lubrication.

- Coupling Alignment: Check and correct the alignment of the driving and driven shafts connected by the coupling. Misalignment can lead to premature wear and reduce coupling efficiency.

- Bolt Tightening: Regularly check and tighten the bolts and fasteners securing the coupling. Loose bolts can lead to coupling slippage and compromised power transmission.

- Cleanliness: Keep the hydraulic coupling and its surrounding area clean from dirt, debris, and contaminants. Clean the coupling during scheduled maintenance to prevent contamination-related issues.

- Temperature and Pressure Checks: Monitor the operating temperature and pressure to ensure they remain within the specified limits for the coupling. Operating beyond the recommended ranges can cause damage and reduce coupling performance.

- Overload Prevention: Avoid exceeding the rated torque capacity of the coupling to prevent overload and potential damage to the coupling or connected equipment.

- Replacement of Worn Parts: Replace any worn or damaged components of the hydraulic coupling promptly. Follow the manufacturer’s guidelines for part replacement and use genuine spare parts when needed.

- Periodic Maintenance: Establish a regular maintenance schedule for the hydraulic coupling based on the operating conditions and manufacturer recommendations. Adhering to this schedule helps identify and address issues before they become severe.

- Expert Inspection: If you encounter any unusual performance issues or suspect coupling problems, consult a hydraulic system expert for a detailed inspection and analysis. They can provide valuable insights and recommendations for maintenance and repairs.

Proper and consistent maintenance of hydraulic couplings is essential to ensure their reliability, efficiency, and safe operation. By following the recommended maintenance practices, you can prolong the life of the hydraulic coupling and optimize the performance of your hydraulic system.

Can hydraulic couplings be retrofitted into existing hydraulic systems for improved performance?

Yes, hydraulic couplings can be retrofitted into existing hydraulic systems to enhance performance, improve reliability, and address specific system requirements. Retrofitting hydraulic couplings can be a cost-effective way to upgrade older systems without the need for extensive modifications or complete replacements.

Retrofitting hydraulic couplings may be beneficial for several reasons:

- Improved Efficiency: Upgrading to modern hydraulic couplings with better design features can reduce energy losses and improve overall system efficiency. For example, switching from older, less efficient couplings to newer, more streamlined designs can optimize fluid flow and reduce pressure drop.

- Leak Reduction: Older hydraulic systems may experience fluid leaks due to worn-out or damaged couplings. Retrofitting with new, high-quality couplings equipped with advanced sealing technologies can significantly reduce the risk of leaks, leading to better system reliability and environmental safety.

- Higher Pressure and Flow Capabilities: Newer hydraulic couplings may offer higher pressure and flow ratings, allowing the system to handle increased demands or heavier loads. This can be crucial for applications that require more power and performance.

- Material Compatibility: In some cases, existing hydraulic systems may have components made from materials that are not compatible with certain hydraulic fluids. Retrofitting with appropriate couplings can ensure compatibility and prevent corrosion or other fluid-related issues.

- Space Constraints: Modern hydraulic couplings often come in more compact designs, which can be advantageous for systems with limited space. Retrofitting with smaller couplings may allow for better system integration and improved layout.

- Environmental Compliance: Retrofitting hydraulic couplings can help align the system with current environmental regulations and industry standards, reducing the risk of potential fines or non-compliance issues.

Before retrofitting hydraulic couplings, careful evaluation of the existing system is necessary to ensure compatibility and identify specific areas for improvement. Factors such as thread type, size, pressure rating, flow capacity, and material compatibility must be considered to select the appropriate couplings for the retrofit.

It’s essential to consult with hydraulic coupling manufacturers or experienced fluid power professionals when planning a retrofit. They can provide guidance on suitable coupling options and recommend the necessary modifications or adjustments to optimize system performance.

In conclusion, retrofitting hydraulic couplings into existing hydraulic systems can be a viable solution for enhancing performance, reducing leaks, and achieving better overall efficiency and reliability. It allows businesses to leverage the latest advancements in hydraulic coupling technology to extend the lifespan and improve the functionality of their existing hydraulic systems.

Are there specific pressure and temperature limits for different hydraulic coupling designs?

Yes, different hydraulic coupling designs have specific pressure and temperature limits, and these limits can vary based on the coupling type and construction materials. Here are some general considerations regarding pressure and temperature limits for common hydraulic coupling designs:

- Jaw Couplings: Jaw couplings typically have a pressure rating ranging from 1000 psi to 5000 psi (6.9 MPa to 34.5 MPa) and can handle temperatures from -20°C to 120°C (-4°F to 248°F). These couplings are suitable for various industrial applications with moderate pressure and temperature requirements.

- Disc Couplings: Disc couplings offer higher pressure and temperature capabilities compared to jaw couplings. Their pressure rating can range from 2000 psi to 6000 psi (13.8 MPa to 41.4 MPa), and they can handle temperatures between -50°C to 150°C (-58°F to 302°F). These couplings are commonly used in high-performance and precision equipment.

- Fluid Couplings: Fluid couplings are suitable for applications requiring smooth start-ups and shock absorption. Their pressure limits can range from 150 psi to 3000 psi (1.03 MPa to 20.7 MPa), and they can handle temperatures from -40°C to 150°C (-40°F to 302°F). These couplings are often used in heavy machinery, such as conveyors and crushers.

- Gear Couplings: Gear couplings have a higher pressure rating, typically ranging from 2500 psi to 8000 psi (17.2 MPa to 55.2 MPa), and can handle temperatures from -20°C to 150°C (-4°F to 302°F). These couplings are commonly used in heavy-duty industrial applications with high torque requirements.

- Oldham Couplings: Oldham couplings have pressure limits ranging from 500 psi to 3000 psi (3.4 MPa to 20.7 MPa) and can handle temperatures between -30°C to 100°C (-22°F to 212°F). They are suitable for applications where shafts are not in perfect alignment.

- Diaphragm Couplings: Diaphragm couplings offer high pressure and temperature capabilities. Their pressure rating can range from 3000 psi to 10000 psi (20.7 MPa to 68.9 MPa), and they can handle temperatures from -50°C to 200°C (-58°F to 392°F). These couplings are commonly used in high-speed and high-temperature applications like pumps and compressors.

- Beam Couplings: Beam couplings typically have a pressure rating ranging from 1000 psi to 4000 psi (6.9 MPa to 27.6 MPa) and can handle temperatures between -40°C to 150°C (-40°F to 302°F). They are commonly used in precision equipment and motion control applications.

It’s essential to consult the manufacturer’s specifications and guidelines for each specific hydraulic coupling design to ensure it is suitable for the intended application’s pressure and temperature requirements. Using a coupling within its specified limits ensures safe and reliable operation and maximizes the performance and lifespan of the hydraulic system.

editor by CX 2024-04-24

China OEM Hydraulic Hose Fittings Steel Pipe Repair Stainless Steel Fire Hose Couplings

Product Description

Dimension:All size, according to your requirement

Material:Stainless Steel SS304, SS316, SS316L

Grade:A2-50, A2-70, A2-80, A4-70, A4-80

Service:OEM ODM

Standard:BSP,JIC,PT,PF,NPT,DIN,Metric

Tolerance:+-0.01mm

Application:Seal hydraulic fitting used to connect with hose

| Product Name | Hydraulic Hose Fittings Steel Pipe Repair Stainless Steel Fire Hose Couplings |

| Packaging | Bulk Packaging,Small Box(glue box,color box) & Carton&Wooden Pallet(Europallet 1200*800mm) or According to customer’s requirement |

| Trade Term | EXW,FOB,CIF,CFR,CNF |

| Payment Term | T/T,Western Union,Paypal,L/C |

| Shipping Port | HangZhou,Zhapu,ZheJiang |

| Advantages | • Professional and experienced production,quality inspection,package,design and sales team • Response within 2 hours • Full stock for almost standard fasteners • Fast delivery and response • Samples available |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can hydraulic couplings handle both angular and axial misalignments simultaneously?

Yes, hydraulic couplings are designed to handle both angular and axial misalignments simultaneously. These couplings have inherent flexibility in their design, allowing them to accommodate various types of misalignments between the driving and driven shafts.

Angular misalignment occurs when the axes of the two shafts are not collinear, resulting in an angle between them. Axial misalignment, on the other hand, refers to the offset between the two shafts along their axis. Hydraulic couplings can compensate for these misalignments without sacrificing their ability to transmit torque efficiently.

The design of hydraulic couplings typically includes features such as flexible elements, torsional flexibility, or a fluid medium that allows the coupling to absorb and compensate for misalignments. When misalignment occurs, the flexible elements or fluid within the coupling act as a buffer, transmitting torque smoothly and reducing stress on the connected components.

By accommodating both angular and axial misalignments, hydraulic couplings offer several advantages in various applications:

- Reduced Wear: Hydraulic couplings’ ability to handle misalignments helps reduce wear and tear on the shafts, bearings, and other components, prolonging the life of the equipment.

- Smooth Operation: The ability to compensate for misalignments results in smoother operation and reduced vibrations, contributing to overall system performance and precision.

- Overload Protection: Hydraulic couplings can provide overload protection by allowing slippage when torque exceeds the coupling’s capacity, protecting the system from damage.

- Shock Absorption: In systems subject to shock loads or sudden changes in torque, hydraulic couplings can absorb and dampen these shocks, preventing damage to the equipment.

- Maintenance Reduction: By minimizing stress on the system components, hydraulic couplings can help reduce maintenance requirements and downtime.

It is important to note that the extent of misalignment accommodation may vary depending on the specific design and type of hydraulic coupling. Manufacturers provide guidelines and specifications for each coupling, including the maximum allowable misalignments.

Overall, hydraulic couplings’ ability to handle both angular and axial misalignments simultaneously makes them a versatile choice for various industrial applications where precision, efficiency, and reliable power transmission are essential.

What are the standard sizes and thread types available for hydraulic couplings?

Hydraulic couplings come in a variety of sizes and thread types to accommodate different hydraulic system requirements. The standard sizes and thread types are specified based on industry standards and regional norms. Here are some common standard sizes and thread types for hydraulic couplings:

- Thread Types:

- NPT (National Pipe Thread): NPT is a widely used thread type in North America. It has a tapered thread design and requires thread sealants like Teflon tape to ensure a leak-free connection.

- BSP (British Standard Pipe): BSP is commonly used in Europe and many other parts of the world. It can have parallel (BSPP) or tapered (BSPT) threads and often requires thread sealants for a secure connection.

- JIC (Joint Industry Council): JIC threads have a 37-degree flare angle and are prevalent in hydraulic systems. They provide a reliable metal-to-metal seal without the need for thread sealants.

- SAE (Society of Automotive Engineers): SAE threads are commonly used in mobile hydraulic applications. They have a 45-degree flare angle and offer excellent sealing capabilities.

- ORFS (O-Ring Face Seal): ORFS fittings feature a flat face with an O-ring seal. They are suitable for high-pressure applications and provide a reliable leak-free connection.

- Standard Sizes:

- Hydraulic couplings are available in various standard sizes, typically measured in inches or millimeters. Common sizes for hydraulic couplings include 1/4″, 3/8″, 1/2″, 3/4″, 1″, and 1 1/4″ for smaller couplings and up to larger sizes like 2″, 2 1/2″, and 3″ for heavy-duty industrial applications.

- Metric sizes, such as 6 mm, 10 mm, 12 mm, 16 mm, and 20 mm, are also commonly used in hydraulic systems, especially in countries that follow the metric system.

- Some specialized hydraulic systems may require custom sizes to meet specific application needs.

It’s important to note that while these thread types and sizes are commonly used, there may be other proprietary or industry-specific thread types and sizes depending on the manufacturer or application requirements. When selecting hydraulic couplings, it’s essential to ensure that the chosen couplings match the thread type and size of the corresponding components in the hydraulic system to ensure a proper and secure connection.

Hydraulic coupling manufacturers often provide detailed specifications and technical information about their products, including the available thread types and sizes, to help users select the right couplings for their specific hydraulic system needs.

Can you explain the working principle of a hydraulic coupling and its advantages over other coupling types?

A hydraulic coupling operates based on the principle of hydraulic fluid transmission to transfer power from one shaft to another. It consists of two main parts: the input (driving) element and the output (driven) element, both of which have specially designed vanes or blades submerged in hydraulic fluid.

When the input element rotates, it creates a flow of hydraulic fluid around the vanes. The fluid flow generates pressure on the output element, causing it to start rotating. This pressure difference between the input and output elements facilitates the transfer of torque and power from the driving shaft to the driven shaft.

The working principle of a hydraulic coupling allows it to accommodate misalignments and torsional vibrations. It effectively isolates shock loads, provides overload protection, and dampens vibrations, making it ideal for various industrial applications.

Advantages of hydraulic couplings over other coupling types include:

- Misalignment Tolerance: Hydraulic couplings can handle significant shaft misalignments, reducing wear and tear on the system and prolonging the life of the components. Other coupling types may have limitations in this regard.

- Vibration Damping: Hydraulic couplings can effectively dampen vibrations, preventing damage to connected equipment and promoting smoother operation. This advantage is especially critical in precision machinery and applications where vibrations can affect accuracy and performance.

- Overload Protection: Hydraulic couplings offer built-in overload protection. When the torque exceeds a certain threshold, the fluid coupling slips or disengages, preventing damage to the system and its components. Other coupling types may not have this automatic overload protection.

- Smooth Start-up: Hydraulic couplings provide gradual power transmission during start-up, which helps minimize shock and stress on the system. This feature is beneficial for systems with heavy loads or delicate components.

- Quiet Operation: Due to their vibration-damping properties, hydraulic couplings contribute to quieter operation, reducing noise levels in the machinery compared to some other coupling types.

- Wide Range of Applications: Hydraulic couplings are suitable for a wide range of industrial applications, including heavy machinery, mining equipment, conveyors, pumps, and more. Their adaptability and robust performance make them a popular choice in various industries.

While hydraulic couplings offer many advantages, the selection of the appropriate coupling type ultimately depends on the specific requirements of the application, such as torque, speed, misalignment, and environmental conditions. Properly choosing and maintaining the coupling can significantly improve the efficiency, reliability, and overall performance of fluid power transmission systems in industrial settings.

editor by CX 2024-04-19

China Best Sales Hydraulic System Hydraulic Hose Crimping Fittings and Couplings

Product Description

| Material | Brass,Copper,Stainless steel,Plastic (according to customer’s requirement) |

| Package Way | Standars Carton+pallet or Customized like Blister all ok |

| LeadTime | 30 days as usual, it will base on the order QTY and delivery due to customer’s plan |

| Payment | T/T or L/C |

| MOQ: | 1000PCS |

| Transportation | By sea or By air |

| Equipment | Forging Machine, CNC machine,stamping machine, sand blasting machine etc |

| Customized | Customized are welcome |

| QC Inspection | 100% inspection before package and delivery |

| Factory Experience | More than 20 years manufacture and customized products experience |

| Certificate | ISO9001:2015, ROHS, SGS, Material Certification |

| Sample | Samples and Dimensions report will offer to customer for confirmati |

workshop

FAQ

1), Q: How can I get a sample?

A: Yes, if customer want, we will express couple pcs samples free for customer to check before we arrange batch producing, we would like to talk with customer to get your kindly advise .

2), Q: How Your Factory Control the Quality ?

A: We control the quality since Material arrive, we have workshop QC responsible for each producting line to check the product dimensions and other details during 1 by 1 producing process, inspection QC do spot check for each batch in everyday and package workers do 100% product appearance inspection 1 by 1 when they package the parts into the carton.

We trust quality need to control on the producing line not final step.

3), what’s machine you do for these machining parts?

A: we have high precision machining center to produce for small tolerance products and we also have some automatic CNC machine, CNC machine, stamping machine, automatic drill-hole machine and sandblasting maching etc, except the plating, we do whole producing process in own factory.

We are glad to receive your message, Welcome to contact us. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the maintenance requirements for hydraulic couplings to ensure optimal performance?

Maintaining hydraulic couplings is crucial to ensure their optimal performance and extend their service life. Regular maintenance helps identify potential issues early on and prevents costly breakdowns. Here are the essential maintenance requirements for hydraulic couplings:

- Inspection: Regularly inspect the hydraulic coupling for signs of wear, damage, or leaks. Check for any unusual noises, vibrations, or changes in performance during operation.

- Lubrication: Ensure proper lubrication of the coupling’s moving parts. Use the manufacturer-recommended lubricants and follow the specified intervals for re-lubrication.

- Coupling Alignment: Check and correct the alignment of the driving and driven shafts connected by the coupling. Misalignment can lead to premature wear and reduce coupling efficiency.

- Bolt Tightening: Regularly check and tighten the bolts and fasteners securing the coupling. Loose bolts can lead to coupling slippage and compromised power transmission.

- Cleanliness: Keep the hydraulic coupling and its surrounding area clean from dirt, debris, and contaminants. Clean the coupling during scheduled maintenance to prevent contamination-related issues.

- Temperature and Pressure Checks: Monitor the operating temperature and pressure to ensure they remain within the specified limits for the coupling. Operating beyond the recommended ranges can cause damage and reduce coupling performance.

- Overload Prevention: Avoid exceeding the rated torque capacity of the coupling to prevent overload and potential damage to the coupling or connected equipment.

- Replacement of Worn Parts: Replace any worn or damaged components of the hydraulic coupling promptly. Follow the manufacturer’s guidelines for part replacement and use genuine spare parts when needed.

- Periodic Maintenance: Establish a regular maintenance schedule for the hydraulic coupling based on the operating conditions and manufacturer recommendations. Adhering to this schedule helps identify and address issues before they become severe.

- Expert Inspection: If you encounter any unusual performance issues or suspect coupling problems, consult a hydraulic system expert for a detailed inspection and analysis. They can provide valuable insights and recommendations for maintenance and repairs.

Proper and consistent maintenance of hydraulic couplings is essential to ensure their reliability, efficiency, and safe operation. By following the recommended maintenance practices, you can prolong the life of the hydraulic coupling and optimize the performance of your hydraulic system.

Can hydraulic couplings be retrofitted into existing hydraulic systems for improved performance?

Yes, hydraulic couplings can be retrofitted into existing hydraulic systems to enhance performance, improve reliability, and address specific system requirements. Retrofitting hydraulic couplings can be a cost-effective way to upgrade older systems without the need for extensive modifications or complete replacements.

Retrofitting hydraulic couplings may be beneficial for several reasons:

- Improved Efficiency: Upgrading to modern hydraulic couplings with better design features can reduce energy losses and improve overall system efficiency. For example, switching from older, less efficient couplings to newer, more streamlined designs can optimize fluid flow and reduce pressure drop.

- Leak Reduction: Older hydraulic systems may experience fluid leaks due to worn-out or damaged couplings. Retrofitting with new, high-quality couplings equipped with advanced sealing technologies can significantly reduce the risk of leaks, leading to better system reliability and environmental safety.

- Higher Pressure and Flow Capabilities: Newer hydraulic couplings may offer higher pressure and flow ratings, allowing the system to handle increased demands or heavier loads. This can be crucial for applications that require more power and performance.

- Material Compatibility: In some cases, existing hydraulic systems may have components made from materials that are not compatible with certain hydraulic fluids. Retrofitting with appropriate couplings can ensure compatibility and prevent corrosion or other fluid-related issues.

- Space Constraints: Modern hydraulic couplings often come in more compact designs, which can be advantageous for systems with limited space. Retrofitting with smaller couplings may allow for better system integration and improved layout.

- Environmental Compliance: Retrofitting hydraulic couplings can help align the system with current environmental regulations and industry standards, reducing the risk of potential fines or non-compliance issues.

Before retrofitting hydraulic couplings, careful evaluation of the existing system is necessary to ensure compatibility and identify specific areas for improvement. Factors such as thread type, size, pressure rating, flow capacity, and material compatibility must be considered to select the appropriate couplings for the retrofit.

It’s essential to consult with hydraulic coupling manufacturers or experienced fluid power professionals when planning a retrofit. They can provide guidance on suitable coupling options and recommend the necessary modifications or adjustments to optimize system performance.

In conclusion, retrofitting hydraulic couplings into existing hydraulic systems can be a viable solution for enhancing performance, reducing leaks, and achieving better overall efficiency and reliability. It allows businesses to leverage the latest advancements in hydraulic coupling technology to extend the lifespan and improve the functionality of their existing hydraulic systems.

Can you explain the working principle of a hydraulic coupling and its advantages over other coupling types?

A hydraulic coupling operates based on the principle of hydraulic fluid transmission to transfer power from one shaft to another. It consists of two main parts: the input (driving) element and the output (driven) element, both of which have specially designed vanes or blades submerged in hydraulic fluid.

When the input element rotates, it creates a flow of hydraulic fluid around the vanes. The fluid flow generates pressure on the output element, causing it to start rotating. This pressure difference between the input and output elements facilitates the transfer of torque and power from the driving shaft to the driven shaft.

The working principle of a hydraulic coupling allows it to accommodate misalignments and torsional vibrations. It effectively isolates shock loads, provides overload protection, and dampens vibrations, making it ideal for various industrial applications.

Advantages of hydraulic couplings over other coupling types include: