Product Description

SongQiao LSQ-FF Series couplings are widely used in the public utility market where hydraulic oil spillage can constitute a serious safety hazard, particularly in overhead bucket hoists that are used for maintenance of high-voltage power transmission lines.These couplings are also used for quick change of hydraulic Tools in construction, railway maintenance and mining industries. The ease of cleaning makes them ideal for use in these types of hostile environments.

New valve design. it can resistance damage from high flow and the pressure of impulse that providing advanced performance.

Sleeve locking mechanism is engaged by rotating sleeve after connection. It prevents accidental disconnection when, The coupling is dragged along the ground.

Sleeve mechanism is designed to prevent dirt from entering the internal the internal mechanism and thus causing faulty operation when connecting or disconnecting. The sleeve covers the retaining ring and also incorporates a dust seal in the spring area.

Steel construction, zinc plated with yellow chromate finish. hardened nipples and sleeves and CHINAMFG barstock construction for maximum resistance to damage from hydraulic and mechanical shock.

This Anti Blowout Nitrile/PTFE bonded seal is designed to prevent blow-out or damage during severe service conditions.

Durable ball-locking mechanism assures reliable connections ,every time. A large number of locking balls distributes the work load evenly while providing alignment and swiveling action to reduce hose torque and prolong hose life. CAUTION: These products are not not to be used as swivels. Rotation under pressure will result in excessive and premature wear.

LSQ-FF Series couplings employ flush valving when connecting or disconnecting. This means that the valves are mated together so that only small amounts of fluid can be lost during disconnection or air inclusion during reconnection.

New chrome plating treatment provides advanced anti-rust performance.

LSQ-FF series conforms to standard of ISO16571.

Compatible with CHINAMFG FE Series,FFSeries,STUCCHIA8008 Series, AEROQUIP FD89 Series and HANSENQA2900 Series.

| ISO | PART NO | LS | D | HEX1 | A | T |

| 6.3 | LSQ-FF-02SF | 58.2 | 28 | 20 | 14 | G1/4 NPT1/4 |

| 10 | LSQ-FF-03SF | 68.2 | 32 | 24 | 14 | G3/8 NPT3/8 |

| 10 | LSQ-FF-03SF | 72.2 | 32 | 27 | 18 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04SF | 75 | 38 | 32 | 18 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04SF | 79 | 38 | 36 | 22 | G3/4 NPT3/4 |

| 16 | LSQ-FF-06SF | 80 | 42 | 36 | 22 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08SF | 99.8 | 48 | 41 | 22 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08SF | 99.8 | 48 | 41 | 23.5 | G1 NPT1 |

| 25 | LSQ-FF-10SF | 111.5 | 56 | 55 | 24 | G1-1/4 NPT1-1/4 |

| – | LSQ-FF-12SF | 150 | 79.5 | 65 | 30 | G1-1/2 NPT1-1/2 |

| – | LSQ-FF-16SF | 167 | 98.5 | 85 | 31 | G2 NPT2 |

| ISO | PART NO | LP | d | C | HEX2 | A | T |

| 6.3 | LSQ-FF-02PF | 49.2 | 16.1 | 15.2 | 20 | 14 | G1/4 NPT1/4 |

| 10 | LSQ-FF-03PF | 55.8 | 19.7 | 19.5 | 24 | 14 | G3/8 NPT3/8 |

| 10 | LSQ-FF-03PF | 59.8 | 19.7 | 19.5 | 27 | 18 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04PF | 72 | 24.5 | 21.6 | 32 | 18 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04PF | 76 | 24.5 | 21.6 | 36 | 22 | G3/4 NPT3/4 |

| 16 | LSQ-FF-06PF | 75.5 | 27 | 21.6 | 36 | 22 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08PF | 93.8 | 30 | 29 | 41 | 22 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08PF | 93.8 | 30 | 29 | 41 | 23.5 | G1 NPT1 |

| 25 | LSQ-FF-10PF | 90 | 36 | 34 | 55 | 24 | G1-1/4 NPT1-1/4 |

| – | LSQ-FF-12PF | 112 | 57 | 38 | 65 | 30 | G1-1/2 NPT1-1/2 |

| – | LSQ-FF-16PF | 123.9 | 73 | 40.5 | 75 | 31 | G2 NPT2 |

| ISO | PART NO | L | D | HEX1 | HEX2 | T |

| 6.3 | LSQ-FF-02 | 96.2 | 28 | 20 | 20 | G1/4 NPT1/4 |

| 10 | LSQ-FF-03 | 108.4 | 32 | 24 | 24 | G3/8 NPT3/8 |

| 10 | LSQ-FF-03 | 116.4 | 32 | 27 | 27 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04 | 129.3 | 38 | 32 | 32 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04 | 137.3 | 38 | 36 | 36 | G3/4 NPT3/4 |

| 16 | LSQ-FF-06 | 138 | 42 | 36 | 36 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08 | 172.1 | 48 | 41 | 41 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08 | 172.1 | 48 | 41 | 41 | G1 NPT1 |

| 25 | LSQ-FF-10 | 178 | 56 | 55 | 55 | G1-1/4 NPT1-1/4 |

| – | LSQ-FF-12 | 233.4 | 79.5 | 65 | 65 | G1-1/2 NPT1-1/2 |

| – | LSQ-FF-16 | 251.7 | 98.5 | 85 | 75 | G2 NPT2 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can hydraulic couplings handle both angular and axial misalignments simultaneously?

Yes, hydraulic couplings are designed to handle both angular and axial misalignments simultaneously. These couplings have inherent flexibility in their design, allowing them to accommodate various types of misalignments between the driving and driven shafts.

Angular misalignment occurs when the axes of the two shafts are not collinear, resulting in an angle between them. Axial misalignment, on the other hand, refers to the offset between the two shafts along their axis. Hydraulic couplings can compensate for these misalignments without sacrificing their ability to transmit torque efficiently.

The design of hydraulic couplings typically includes features such as flexible elements, torsional flexibility, or a fluid medium that allows the coupling to absorb and compensate for misalignments. When misalignment occurs, the flexible elements or fluid within the coupling act as a buffer, transmitting torque smoothly and reducing stress on the connected components.

By accommodating both angular and axial misalignments, hydraulic couplings offer several advantages in various applications:

- Reduced Wear: Hydraulic couplings’ ability to handle misalignments helps reduce wear and tear on the shafts, bearings, and other components, prolonging the life of the equipment.

- Smooth Operation: The ability to compensate for misalignments results in smoother operation and reduced vibrations, contributing to overall system performance and precision.

- Overload Protection: Hydraulic couplings can provide overload protection by allowing slippage when torque exceeds the coupling’s capacity, protecting the system from damage.

- Shock Absorption: In systems subject to shock loads or sudden changes in torque, hydraulic couplings can absorb and dampen these shocks, preventing damage to the equipment.

- Maintenance Reduction: By minimizing stress on the system components, hydraulic couplings can help reduce maintenance requirements and downtime.

It is important to note that the extent of misalignment accommodation may vary depending on the specific design and type of hydraulic coupling. Manufacturers provide guidelines and specifications for each coupling, including the maximum allowable misalignments.

Overall, hydraulic couplings’ ability to handle both angular and axial misalignments simultaneously makes them a versatile choice for various industrial applications where precision, efficiency, and reliable power transmission are essential.

Where can I find reputable suppliers or manufacturers of hydraulic couplings for my specific hydraulic system requirements?

Finding reputable suppliers or manufacturers of hydraulic couplings is essential to ensure the quality, performance, and compatibility of the couplings with your specific hydraulic system requirements. Here are some methods and sources to help you locate reliable hydraulic coupling suppliers:

- Online Directories and Marketplaces: Utilize online industrial directories and marketplaces that list hydraulic coupling manufacturers and suppliers. Websites like ThomasNet, Alibaba, and IndustryNet can provide comprehensive listings with company profiles and product offerings.

- Trade Shows and Exhibitions: Attend trade shows and exhibitions focused on fluid power and hydraulic components. These events offer an opportunity to meet suppliers in person, see product demonstrations, and discuss your specific requirements directly with the manufacturers.

- Industry Associations: Many industry associations, such as the International Fluid Power Society (IFPS) or the National Fluid Power Association (NFPA), maintain directories of member companies that offer hydraulic couplings and related products. These associations often have strict membership criteria, which can serve as a marker of reputable companies.

- Online Search Engines: Conduct a targeted search using online search engines. Use specific keywords related to your hydraulic system requirements, such as “high-pressure hydraulic couplings” or “quick-connect hydraulic couplings,” along with your location to find local suppliers.

- Manufacturer Websites: Visit the websites of well-known hydraulic coupling manufacturers. Reputable manufacturers often provide detailed product information, specifications, and contact details, making it easier to assess their suitability for your requirements.

- Customer Reviews and Testimonials: Look for customer reviews and testimonials to gauge the reputation and customer satisfaction of potential hydraulic coupling suppliers. Positive feedback from other customers can be an indicator of reliable and reputable manufacturers.

When evaluating hydraulic coupling suppliers, consider the following factors to ensure they meet your specific requirements:

- Product Range: Check if the supplier offers a diverse range of hydraulic couplings, including the types, sizes, and configurations that match your needs.

- Quality Assurance: Inquire about the supplier’s quality control processes and certifications to ensure their hydraulic couplings meet industry standards and regulatory requirements.

- Customization Options: If your hydraulic system requires specialized couplings, confirm if the supplier can provide customization options to meet your unique specifications.

- Technical Support: Assess the supplier’s technical expertise and support capabilities to assist with product selection, installation, and troubleshooting.

- Pricing and Delivery: Obtain competitive pricing and inquire about delivery lead times to ensure the supplier can meet your budget and project timelines.

- After-Sales Service: Inquire about the supplier’s after-sales service, warranty policies, and availability of spare parts to ensure long-term support for your hydraulic couplings.

By conducting thorough research and due diligence, you can find reputable suppliers or manufacturers of hydraulic couplings that align with your specific hydraulic system requirements. Working with reliable suppliers will help you obtain high-quality couplings that contribute to the efficient and reliable operation of your hydraulic system.

How do you select the appropriate hydraulic coupling for specific fluid handling needs?

Selecting the right hydraulic coupling for specific fluid handling needs involves considering several critical factors to ensure optimal performance and reliability. Here’s a step-by-step guide to help you make an informed choice:

- Fluid Type: Identify the type of fluid that the coupling will handle. Different fluids have varying viscosities and chemical properties, which can impact the compatibility and material selection for the coupling.

- Operating Pressure and Temperature: Determine the maximum operating pressure and temperature that the coupling will experience. Ensure that the selected coupling is rated to handle the expected pressure and temperature levels without failure or deformation.

- Torque Requirements: Calculate the required torque capacity based on the power transmission needs of your system. Choose a coupling that can handle the anticipated torque while considering safety factors.

- Misalignment Tolerance: Evaluate the potential misalignments that may occur between the shafts in your system. Choose a coupling that offers sufficient misalignment tolerance to accommodate these variations without imposing excessive stress on the equipment.

- Vibration and Shock: Consider the level of vibration and shock the coupling will experience during operation. Select a coupling that can dampen vibrations and absorb shocks to protect the system components and ensure stable performance.

- Installation and Maintenance: Assess the ease of installation and maintenance requirements of the coupling. A well-designed coupling should be easy to install, inspect, and maintain, reducing downtime and maintenance costs.

- Environmental Factors: Take into account the environmental conditions in which the coupling will operate. Factors such as exposure to moisture, chemicals, dust, or extreme temperatures may affect the choice of coupling materials and coatings.

- Space Constraints: Consider the available space for installing the coupling. Some applications may have limited space, necessitating the use of compact or low-profile couplings.

- Coupling Type: Based on the above considerations, choose the most suitable coupling type for your specific fluid handling needs. Consider options such as jaw couplings, disc couplings, fluid couplings, gear couplings, or other specialized couplings based on your application requirements.

It’s essential to consult with coupling manufacturers or industry experts if you have specific or challenging application requirements. They can provide valuable insights and recommendations to ensure you select the right hydraulic coupling that meets your fluid handling needs and maximizes the efficiency and reliability of your system.

editor by CX 2024-05-15

China Custom Long Life Coupling Used on Flexible Pressure Hydraulic Rubber Hose

Product Description

Long Life Coupling Used On Flexible Pressure Hydraulic Rubber Hose

Hydraulic hose fittings:

Material: stainless steel, carbon steel, brass, etc

Connection: Male/Female

Surface Treatment: Trivalent Silver Zinc, Trivalent Yellow Zinc, Hexavalent Yellow Zinc, Chrome Plate, Electric-polish etc.

Application: Automobile, Engineering Machinery, Lathe, Agriculture Machine, Mining, Spurting the Oil Paint, Metallurgy petroleum , Construction, Chemicals, Textile, Ships, Ocean, Military, Recreation, Electronics and so forth.

Process Characteristics:

High quality carbon steel rigid embryo is selected and manufactured by special machine tool. Hot melt special equipment processing, and equipped with efficient cleaning agent, high flushing, high accuracy and cleanliness. There is no oxide layer after heat treatment. Fully meet the requirements of high temperature, high pressure, corrosion resistance and so on. 96 hours of salt spray test and sealant are used for galvanizing. Rustproof, anticorrosive, superior performance, delicate surface, beautiful color.

Our QC procedure:

As we had more than 5 professional and technical personal, they ensure 100% products checking.

1. Material checking: strictly control of material using, meet international requested standards;

2. semi-finished products inspection: product inspection before 100% finished ;

3. production line test: with work team or data engineer who will inspect matchines and lines at fixed period.

4. finished prodcuct inspection: quality and property test before products are plated zinc, packed and loaded.

Shipping

1. Orders will be dispatched around in 30 days after payment, depending on quantities.

2. We Always choose the most economical and reliable shipping company to make sure you receive the goods in time.

3. The tracking number will be provided to you once the consignment is shipped

4. Professional customer service to answer your questions or fix problems regarding your order.

Our Service

1. OEM Manufacturing welcome: Product, Package…

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every 2 days, until you get the products. When you got the goods, test them, and give me a feedback. If you have any questions about the problem, contact with us, we will offer the solve way for you.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our hose in woven package, fittings in carton box. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 10 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, the customers no need to pay the sample cost but need pay the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

We Sincerely Welcome Partners All Over The World To Visit Us For CHINAMFG Cooperation!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can hydraulic couplings be used in applications involving corrosive or aggressive fluids?

Yes, hydraulic couplings can be used in applications involving corrosive or aggressive fluids, but the choice of materials and design considerations is critical to ensure compatibility and long-term performance. Corrosive fluids, such as acids, alkalis, and certain chemicals, can pose significant challenges to hydraulic systems. Here are some key factors to consider when using hydraulic couplings in such applications:

- Material Selection: Choose hydraulic couplings made from materials that are resistant to the specific corrosive fluid being handled. Stainless steel, certain alloys, and corrosion-resistant coatings are common choices for couplings in corrosive environments.

- Sealing Solutions: Ensure that the couplings have effective sealing solutions to prevent fluid leakage. High-quality seals and gaskets that are compatible with the corrosive fluid are essential to maintain system integrity.

- Chemical Compatibility: Thoroughly assess the chemical compatibility between the hydraulic fluid and the coupling materials. Consider the fluid’s temperature, concentration, and potential reactions with the coupling components.

- Special Coatings: In some cases, using hydraulic couplings with specialized coatings or treatments can enhance their resistance to corrosion and aggressive fluids.

- Regular Inspection and Maintenance: Implement a stringent inspection and maintenance schedule to monitor the condition of the hydraulic couplings and detect any signs of corrosion or degradation. Promptly replace any damaged or worn couplings to prevent fluid leaks and system failure.

- Fluid Contamination: Corrosive fluids can lead to the formation of contaminants in the hydraulic system. Implement effective filtration and contamination control measures to prevent particle buildup and system damage.

- Operating Conditions: Consider the temperature, pressure, and flow conditions of the system, as these factors can impact the corrosion resistance of the couplings and the overall system performance.

While hydraulic couplings can be used in corrosive or aggressive fluid applications, it is essential to consult with coupling manufacturers or fluid system experts to ensure proper material selection and system design. They can provide guidance on selecting the most suitable hydraulic couplings and recommend additional measures to protect the system from the adverse effects of corrosive fluids.

By employing the right materials, adopting proper maintenance practices, and taking the necessary precautions, hydraulic couplings can effectively function in applications involving corrosive or aggressive fluids, providing reliable and safe fluid power transmission.

How do hydraulic couplings ensure efficient torque transmission and prevent fluid leaks?

Hydraulic couplings are designed with specific features to ensure efficient torque transmission and prevent fluid leaks, making them vital components in hydraulic systems. These features contribute to the overall performance and reliability of the hydraulic system. Here’s how hydraulic couplings achieve these goals:

- High-Quality Materials: Hydraulic couplings are manufactured using high-quality materials, such as steel, stainless steel, brass, or other durable alloys. These materials offer excellent strength and wear resistance, allowing the couplings to withstand high torque and pressure loads without deforming or leaking.

- Precision Machining: Hydraulic couplings undergo precise machining processes to achieve tight tolerances and smooth surfaces. This ensures proper alignment and mating of coupling components, minimizing energy losses and enhancing torque transmission efficiency.

- Sealing Mechanisms: Hydraulic couplings incorporate various sealing mechanisms to prevent fluid leaks. O-rings, seals, or face seals are common sealing methods used in hydraulic couplings. When the coupling components are connected, the seals create a secure barrier, preventing hydraulic fluid from escaping the system.

- Leak-Free Designs: Modern hydraulic couplings often feature leak-free designs that minimize the risk of fluid leakage during operation. These designs utilize advanced sealing technologies and tight tolerances to ensure a reliable and durable connection, even under high-pressure conditions.

- Threaded Connections: Many hydraulic couplings use threaded connections, such as NPT, BSP, JIC, or SAE threads, to create a secure and leak-resistant joint. Properly tightened threaded connections maintain the integrity of the hydraulic system, reducing the likelihood of leaks.

- Quick-Connect Couplings: Quick-connect hydraulic couplings are designed for rapid and easy connection and disconnection, often without the need for additional tools. These couplings use internal valves and seals to ensure a leak-free connection when engaged and prevent fluid leaks when disengaged.

- Hermetically Sealed Couplings: In specific applications, hermetically sealed hydraulic couplings use magnetic coupling technology to provide a non-contact, leak-free transmission of torque and power. These couplings have no physical contact points, making them suitable for critical environments or systems handling hazardous fluids.

The combination of these design features ensures that hydraulic couplings efficiently transmit torque from one component to another while maintaining a secure and reliable seal to prevent fluid leaks. This is particularly important in hydraulic systems, where fluid leakage can lead to reduced performance, increased maintenance, and potential safety hazards.

Proper selection, installation, and maintenance of hydraulic couplings are crucial to optimize their torque transmission capabilities and prevent fluid leaks. Regular inspections and replacement of worn-out seals or damaged couplings are essential to ensure the continued efficiency and safety of the hydraulic system.

In summary, hydraulic couplings play a crucial role in efficient torque transmission and fluid sealing in hydraulic systems. Their robust construction, precision engineering, and advanced sealing technologies contribute to the overall performance and reliability of hydraulic machinery and equipment.

What is a hydraulic coupling, and how does it function in fluid power transmission?

A hydraulic coupling is a mechanical device used in fluid power systems to transmit power from one shaft to another, often at different angles or distances. It facilitates the transfer of hydraulic energy from a prime mover, such as an electric motor or an internal combustion engine, to various hydraulic components, such as pumps, actuators, and cylinders.

The main function of a hydraulic coupling is to transmit rotational motion and power while accommodating misalignments and torsional vibrations. It acts as a link between the driving and driven shafts, ensuring that the hydraulic system operates smoothly and efficiently.

Hydraulic couplings operate based on the principle of hydraulic fluid transmission. The coupling consists of two main parts, the input (driving) and output (driven) elements, both of which have specially designed vanes or blades. These vanes are submerged in hydraulic fluid.

When the input element rotates, it creates a flow of hydraulic fluid around the vanes, which in turn generates pressure on the output element. The pressure difference between the two elements causes the output element to start rotating, effectively transmitting power from the input shaft to the output shaft.

Hydraulic couplings are advantageous in various applications due to their ability to:

- Isolate Shock Loads: They can isolate and dampen shock loads and torsional vibrations, protecting sensitive components from sudden jolts and improving overall system performance.

- Accommodate Misalignment: Hydraulic couplings can accommodate misalignment between the input and output shafts, reducing wear and tear on the system and extending the lifespan of the components.

- Provide Overload Protection: They offer overload protection by slipping or disengaging when the torque exceeds a certain threshold, preventing damage to the system and its components.

- Start-Up Assistance: Hydraulic couplings can provide smooth start-up assistance, gradually transmitting power as the fluid builds up pressure, minimizing shock and stress during system startup.

- Reduce Noise and Vibration: By dampening vibrations and shock loads, hydraulic couplings contribute to quieter and smoother operation of fluid power systems.

Overall, hydraulic couplings play a critical role in fluid power transmission, ensuring efficient power transfer, protecting components from shocks and vibrations, and enhancing the overall performance and reliability of hydraulic systems in various industrial and mobile applications.

editor by CX 2024-05-15

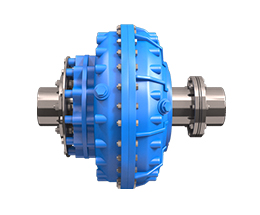

China supplier CHINAMFG Customized Scraper Hydraulic Coupling, Torque Limiting Fluid Coupling

Product Description

Densen Customized Scraper hydraulic coupling,pressure relief type hydraulic coupling,torque limiting fluid coupling

| Product Name | Scraper hydraulic coupling,pressure relief type hydraulic coupling,torque limiting fluid coupling |

| DN mm | 16~190mm |

| Rated Torque | 40~25000 N·m |

| Allowable speed | 4500~200 kN·m |

| Material | 45#steel,aluminum |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Product show

Company Information

Equipment

Application Case

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there specialized hydraulic couplings for high-pressure or high-flow applications?

Yes, there are specialized hydraulic couplings designed to meet the demands of high-pressure and high-flow applications. These specialized couplings are engineered to handle the increased loads, pressures, and flow rates typically encountered in industrial settings where heavy-duty equipment and machinery are used. Here are some types of hydraulic couplings commonly used in such applications:

- High-Pressure Hydraulic Couplings: High-pressure hydraulic couplings are constructed with robust materials and advanced sealing technologies to withstand extreme pressure levels. They are commonly used in hydraulic systems that operate at pressures exceeding standard hydraulic system limits. These couplings ensure reliable power transmission and prevent leakage or failure under high-pressure conditions.

- Quick-Disconnect Couplings: Quick-disconnect couplings, also known as quick-release or quick-connect couplings, are designed for rapid and efficient connection and disconnection of hydraulic lines. They are prevalent in high-flow applications where frequent connections and disconnections are necessary, such as in construction equipment, agricultural machinery, and manufacturing processes.

- Multi-Couplings: Multi-couplings allow the simultaneous connection of multiple hydraulic lines with a single motion. These couplings are suitable for applications with complex hydraulic circuits, such as material handling systems and mobile hydraulics. They simplify the connection process and minimize downtime during equipment setup or maintenance.

- High-Flow Hydraulic Couplings: High-flow hydraulic couplings are designed to accommodate large volumetric flow rates in hydraulic systems. They feature larger passageways and flow channels to reduce pressure drop and ensure efficient fluid transfer in applications like heavy machinery, material handling, and large-scale industrial processes.

- Flush Face Couplings: Flush face couplings provide a leak-free connection when connected or disconnected. They are suitable for high-pressure applications where minimizing fluid loss during connection and disconnection is critical for safety and environmental reasons.

- Flat Face Couplings: Flat face couplings are ideal for high-pressure applications where cleanliness and contamination control are essential. Their flat mating surfaces prevent trapping debris during connection, making them suitable for construction equipment, mining machinery, and other rugged applications.

- High-Temperature Hydraulic Couplings: High-temperature hydraulic couplings are designed to operate in extreme temperature environments, such as those encountered in hot industrial processes or near machinery generating significant heat. They use specialized seals and materials that can withstand elevated temperatures without compromising performance.

Specialized hydraulic couplings are engineered to handle the unique challenges posed by high-pressure or high-flow applications, ensuring safe, efficient, and reliable operation in demanding industrial environments. When selecting a hydraulic coupling for such applications, it’s crucial to consider factors like the specific pressure and flow requirements, environmental conditions, compatibility with the hydraulic fluid, and the overall system design to achieve optimal performance and safety.

Are hydraulic couplings suitable for use in hydraulic cylinders or pumps?

Yes, hydraulic couplings are commonly used in hydraulic cylinders and pumps, playing a crucial role in connecting various components within hydraulic systems. Hydraulic cylinders and pumps are essential components in hydraulic systems, responsible for generating and controlling fluid power to perform mechanical work.

Hydraulic cylinders are actuators that convert fluid pressure into linear motion, producing force and movement. They are widely used in various applications, such as construction machinery, manufacturing equipment, agricultural machinery, and automotive systems.

Hydraulic pumps, on the other hand, are responsible for generating the fluid flow and pressure required to operate hydraulic systems. They provide the driving force that enables hydraulic cylinders and other actuators to perform their intended tasks.

Hydraulic couplings are used in hydraulic cylinders and pumps to connect hoses, tubes, and other hydraulic components. They ensure a secure and leak-free connection, allowing hydraulic fluid to flow between different parts of the system. Some common coupling types used in hydraulic cylinders and pumps include:

- JIC Fittings: JIC (Joint Industry Council) fittings, which have a 37-degree flare angle, are commonly used in high-pressure hydraulic systems, including hydraulic cylinders and pumps. They provide reliable metal-to-metal sealing and are easy to assemble and disassemble.

- ORFS Fittings: ORFS (O-Ring Face Seal) fittings are widely used in high-pressure hydraulic applications. They provide a robust and leak-free connection through an O-ring seal in the face of the fitting.

- NPT Fittings: NPT (National Pipe Thread) fittings, with their tapered threads, are commonly used in lower-pressure hydraulic systems, providing a reliable seal with the use of thread sealants like Teflon tape.

- BSP Fittings: BSP (British Standard Pipe) fittings, available in parallel (BSPP) and tapered (BSPT) threads, are widely used in European hydraulic systems.

Properly selected and installed hydraulic couplings ensure the integrity of the hydraulic system, allowing efficient and reliable power transmission between hydraulic cylinders, pumps, valves, and other components. When using hydraulic couplings in hydraulic cylinders and pumps, it’s essential to consider factors such as the required pressure rating, flow capacity, material compatibility, and environmental conditions to ensure optimal performance and safety.

In summary, hydraulic couplings are essential components in hydraulic systems, making them well-suited for use in hydraulic cylinders and pumps, where they facilitate fluid flow and help maintain the integrity of the overall hydraulic system.

How do hydraulic couplings accommodate misalignment and prevent overload during operation?

Hydraulic couplings are designed to accommodate misalignment and prevent overload during operation, ensuring smooth and efficient power transmission. Here’s how they achieve this:

- Misalignment Accommodation: Hydraulic couplings can handle different types of misalignment between the driving and driven shafts. This includes angular misalignment, radial misalignment, and axial misalignment. The design of the coupling allows it to flex and compensate for these misalignments, reducing stress on the system components and preventing premature wear.

- Torsional Flexibility: Hydraulic couplings offer torsional flexibility, which means they can twist and absorb torsional vibrations that may occur during operation. This capability helps to dampen vibrations and reduce the impact of shock loads on the system, enhancing the overall performance and protecting sensitive components.

- Slip Mechanism: In applications where overload protection is critical, some hydraulic couplings feature a slip mechanism. When the torque exceeds a certain threshold, the coupling slips, disengaging the driving and driven elements. This slip mechanism prevents damage to the system and its components by acting as a safety feature under high-load conditions.

- Hydraulic Fluid Damping: The hydraulic fluid present in the coupling acts as a damping medium. When torque is transmitted from the driving element to the driven element, the fluid dampens the transmission of vibrations, providing a smoother and quieter operation while reducing wear and tear.

- Gradual Start-up: During system start-up, hydraulic couplings provide gradual power transmission. As the fluid flow builds up and pressure increases, the coupling gradually engages, minimizing the shock and stress on the system. This gradual start-up is particularly beneficial for systems with heavy loads and delicate components.

- Continuous Power Transmission: Hydraulic couplings maintain continuous power transmission even when there are slight misalignments or variations in operating conditions. The ability to accommodate misalignments and fluctuations in torque allows the system to operate reliably and efficiently over time.

By accommodating misalignments, damping vibrations, and providing overload protection, hydraulic couplings ensure the smooth and reliable operation of hydraulic systems. Their versatility and adaptability make them suitable for a wide range of industrial applications, where precision, efficiency, and protection against shock loads are essential requirements.

editor by CX 2024-05-15

China OEM BSPT Male Unequal Hex Hydraulic Hose Adapter Coupling

Product Description

| Surface Treatment | Galvazation | Color | White or Yellow |

| Pressure | High Working Pressure | Logo | Laser Print |

| Drawings | OEM or Lt Drawings | Delivery Time | 90 days |

| Name | High Quality Hydraulic pipe Fitting | Steel | 45# Steel |

| Cartification | ISO | Transport Package | Carton Box +Wooden Pallet+Nylon Bag |

| Specification | all size available | Trademark | Custom-made print logo |

| Origin | China Mainland | HS Code | 7357100 |

| Production Capacity | 60000 pieces/Month |

Our Advantages

ZheJiang Beiteer Hydraumatic Equipment Co.,Ltd. specializes in the production and development of various types of hydraulic hose joints,transition joints and hose assembly of 1 of the large enterprises. present,the company has a variety of hydraulic joints,hose assemblies products with excellent structure, advanced design and other characteristics,widely used in engineering,metallurgy,agriculture, machinery,oil fields,ships and other industries of hydraulic and fluid delivery sytems.Our factory can customize products according to customers’ needs.

Company Profile

ZheJiang Beiteer Hydraumatic Equipment Co.,Ltd. specializes in the production and development of various types of hydraulic hose joints,transition joints and hose assembly of 1 of the large enterprises. Annual production of 10million hydraulic hose joints, 5 million transition joints, hose assembly 500,000. After years of hard work, the company now covers an area of 2000 square meters, more than 50 employees,CNC numerical control machine tools, special instrument lathes, Finnish FINN-POWER port press, lock mother machine, surface sandblasting machine, frequency conversion air compressor, saw machine, micro-pneumatic marking machine and other processing equipment, equipped with advanced computers at home and abroad. Control system digital projector, precision flaw detection instrument, working and blasting pressure testing equipment. At the same time, we have trained and set up a team of highly educated and professional staff to continuously strengthen technological innovation and new product research and development.

At present, the company has a variety of hydraulic joints, hose assemblies, products with excellent structure, advanced design and other characteristics, widely used in engineering, metallurgy, agriculture, oil fields, ships and other industries of hydraulic and fluid delivery systems.

With professional team,rigorous management and active marketing strategy, the company has long-term cooperation with many famous domestic companies. Our company always takes “high and new brand, innovation and development, honesty and cooperation” as the enterprise purpose, constantly absorbs advanced technology and technology, constantly optimizes technology and equipment, and improves and improves the detection

means, so as to make the enterprise product quality better. And with thoughtful and timely fixed-point supporting services, to develop into your strategic partners and strive.

FAQ

1.Are you manufactory?

Yes,We have our own factory.

2.How about the samples?

We can send you samples with little and reasonable charge.

3.How about your quality?

You can try a small order and you will have your judgement.

4.What’s your payment term?

L/C, T/T

5.What’s the shipping port?

ZheJiang port

6.Does your factory accept customization?

Yes,we can make them according to your drawings.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the maintenance requirements for hydraulic couplings to ensure optimal performance?

Maintaining hydraulic couplings is crucial to ensure their optimal performance and extend their service life. Regular maintenance helps identify potential issues early on and prevents costly breakdowns. Here are the essential maintenance requirements for hydraulic couplings:

- Inspection: Regularly inspect the hydraulic coupling for signs of wear, damage, or leaks. Check for any unusual noises, vibrations, or changes in performance during operation.

- Lubrication: Ensure proper lubrication of the coupling’s moving parts. Use the manufacturer-recommended lubricants and follow the specified intervals for re-lubrication.

- Coupling Alignment: Check and correct the alignment of the driving and driven shafts connected by the coupling. Misalignment can lead to premature wear and reduce coupling efficiency.

- Bolt Tightening: Regularly check and tighten the bolts and fasteners securing the coupling. Loose bolts can lead to coupling slippage and compromised power transmission.

- Cleanliness: Keep the hydraulic coupling and its surrounding area clean from dirt, debris, and contaminants. Clean the coupling during scheduled maintenance to prevent contamination-related issues.

- Temperature and Pressure Checks: Monitor the operating temperature and pressure to ensure they remain within the specified limits for the coupling. Operating beyond the recommended ranges can cause damage and reduce coupling performance.

- Overload Prevention: Avoid exceeding the rated torque capacity of the coupling to prevent overload and potential damage to the coupling or connected equipment.

- Replacement of Worn Parts: Replace any worn or damaged components of the hydraulic coupling promptly. Follow the manufacturer’s guidelines for part replacement and use genuine spare parts when needed.

- Periodic Maintenance: Establish a regular maintenance schedule for the hydraulic coupling based on the operating conditions and manufacturer recommendations. Adhering to this schedule helps identify and address issues before they become severe.

- Expert Inspection: If you encounter any unusual performance issues or suspect coupling problems, consult a hydraulic system expert for a detailed inspection and analysis. They can provide valuable insights and recommendations for maintenance and repairs.

Proper and consistent maintenance of hydraulic couplings is essential to ensure their reliability, efficiency, and safe operation. By following the recommended maintenance practices, you can prolong the life of the hydraulic coupling and optimize the performance of your hydraulic system.

Can hydraulic couplings be retrofitted into existing hydraulic systems for improved performance?

Yes, hydraulic couplings can be retrofitted into existing hydraulic systems to enhance performance, improve reliability, and address specific system requirements. Retrofitting hydraulic couplings can be a cost-effective way to upgrade older systems without the need for extensive modifications or complete replacements.

Retrofitting hydraulic couplings may be beneficial for several reasons:

- Improved Efficiency: Upgrading to modern hydraulic couplings with better design features can reduce energy losses and improve overall system efficiency. For example, switching from older, less efficient couplings to newer, more streamlined designs can optimize fluid flow and reduce pressure drop.

- Leak Reduction: Older hydraulic systems may experience fluid leaks due to worn-out or damaged couplings. Retrofitting with new, high-quality couplings equipped with advanced sealing technologies can significantly reduce the risk of leaks, leading to better system reliability and environmental safety.

- Higher Pressure and Flow Capabilities: Newer hydraulic couplings may offer higher pressure and flow ratings, allowing the system to handle increased demands or heavier loads. This can be crucial for applications that require more power and performance.

- Material Compatibility: In some cases, existing hydraulic systems may have components made from materials that are not compatible with certain hydraulic fluids. Retrofitting with appropriate couplings can ensure compatibility and prevent corrosion or other fluid-related issues.

- Space Constraints: Modern hydraulic couplings often come in more compact designs, which can be advantageous for systems with limited space. Retrofitting with smaller couplings may allow for better system integration and improved layout.

- Environmental Compliance: Retrofitting hydraulic couplings can help align the system with current environmental regulations and industry standards, reducing the risk of potential fines or non-compliance issues.

Before retrofitting hydraulic couplings, careful evaluation of the existing system is necessary to ensure compatibility and identify specific areas for improvement. Factors such as thread type, size, pressure rating, flow capacity, and material compatibility must be considered to select the appropriate couplings for the retrofit.

It’s essential to consult with hydraulic coupling manufacturers or experienced fluid power professionals when planning a retrofit. They can provide guidance on suitable coupling options and recommend the necessary modifications or adjustments to optimize system performance.

In conclusion, retrofitting hydraulic couplings into existing hydraulic systems can be a viable solution for enhancing performance, reducing leaks, and achieving better overall efficiency and reliability. It allows businesses to leverage the latest advancements in hydraulic coupling technology to extend the lifespan and improve the functionality of their existing hydraulic systems.

How do hydraulic couplings accommodate misalignment and prevent overload during operation?

Hydraulic couplings are designed to accommodate misalignment and prevent overload during operation, ensuring smooth and efficient power transmission. Here’s how they achieve this:

- Misalignment Accommodation: Hydraulic couplings can handle different types of misalignment between the driving and driven shafts. This includes angular misalignment, radial misalignment, and axial misalignment. The design of the coupling allows it to flex and compensate for these misalignments, reducing stress on the system components and preventing premature wear.

- Torsional Flexibility: Hydraulic couplings offer torsional flexibility, which means they can twist and absorb torsional vibrations that may occur during operation. This capability helps to dampen vibrations and reduce the impact of shock loads on the system, enhancing the overall performance and protecting sensitive components.

- Slip Mechanism: In applications where overload protection is critical, some hydraulic couplings feature a slip mechanism. When the torque exceeds a certain threshold, the coupling slips, disengaging the driving and driven elements. This slip mechanism prevents damage to the system and its components by acting as a safety feature under high-load conditions.

- Hydraulic Fluid Damping: The hydraulic fluid present in the coupling acts as a damping medium. When torque is transmitted from the driving element to the driven element, the fluid dampens the transmission of vibrations, providing a smoother and quieter operation while reducing wear and tear.

- Gradual Start-up: During system start-up, hydraulic couplings provide gradual power transmission. As the fluid flow builds up and pressure increases, the coupling gradually engages, minimizing the shock and stress on the system. This gradual start-up is particularly beneficial for systems with heavy loads and delicate components.

- Continuous Power Transmission: Hydraulic couplings maintain continuous power transmission even when there are slight misalignments or variations in operating conditions. The ability to accommodate misalignments and fluctuations in torque allows the system to operate reliably and efficiently over time.

By accommodating misalignments, damping vibrations, and providing overload protection, hydraulic couplings ensure the smooth and reliable operation of hydraulic systems. Their versatility and adaptability make them suitable for a wide range of industrial applications, where precision, efficiency, and protection against shock loads are essential requirements.

editor by CX 2024-05-15

nylon drive coupling

Introduction to Nylon Drive Coupling

1. Durability

Nylon drive couplings are known for their durability and long-lasting performance. The material used in these couplings makes them resistant to wear and tear, ensuring a longer lifespan for your machinery.

2. Flexibility

These couplings offer flexibility in terms of alignment and installation, making them suitable for a wide range of applications. The nylon material allows for some degree of misalignment without compromising performance.

3. Shock Absorption

Nylon drive couplings have excellent shock absorption properties, which helps in reducing vibrations and noise in machinery. This feature also helps in protecting sensitive components from damage.

4. Corrosion Resistance

Due to the nature of the nylon material, these couplings are resistant to corrosion and rust. This makes them suitable for use in various environmental conditions, including humid or corrosive settings.

5. Cost-Effective

Compared to other types of drive couplings, nylon drive couplings are cost-effective without compromising on quality. They offer a balance between performance and affordability, making them a popular choice for many industries.

Types of Drive Couplings

1. Gear Couplings

Gear couplings are used to connect two shafts for transmitting power and torque. They are known for their high torque capacity and backlash-free operation.

2. Grid Couplings

Grid couplings use a flexible grid element to transmit power between two shafts. They offer high misalignment capacity and are suitable for applications with shock loads.

3. Disc Couplings

Disc couplings use a series of thin metal discs to transmit torque between shafts. They provide high torsional stiffness and are ideal for precision applications.

4. Jaw Couplings

Jaw couplings use elastomeric elements to transmit power between shafts. They are easy to install and offer vibration damping properties.

5. Chain Couplings

Chain couplings use roller chains to transmit power between two shafts. They are suitable for high-speed and high-torque applications.

Materials Used in Drive Couplings

1. Steel

Steel is commonly used in drive couplings due to its high strength and durability. It is suitable for heavy-duty applications that require high torque transmission.

2. Aluminum

Aluminum drive couplings are lightweight and offer good corrosion resistance. They are suitable for applications where weight is a concern.

3. Cast Iron

Cast iron is known for its high wear resistance and damping properties. It is suitable for applications with high shock loads and vibrations.

4. Stainless Steel

Stainless steel drive couplings offer excellent corrosion resistance and durability. They are suitable for applications in harsh environments.

5. Nylon

Nylon is a popular material for drive couplings due to its flexibility, shock absorption, and cost-effectiveness. It is suitable for a wide range of applications.

Key Applications of Drive Couplings

1. Industrial Machinery

2. Automotive Industry

3. Aerospace Applications

4. Marine Industry

5. Renewable Energy Sector

Selection Criteria for Drive Couplings

1. Torque Capacity

2. Misalignment Tolerance

3. Environmental Conditions

4. Maintenance Requirements

5. Cost-Effectiveness

About HZPT

Founded in 2006, HZPT is a leading manufacturer and exporter of couplings with a strong focus on quality and customer satisfaction. With 16 years of experience in design and R&D, we provide customized solutions for global customers. Our products are CE and TUV certified, ensuring high standards of quality. We offer competitive prices and excellent service, making us a trusted partner for customers in Europe and the United States. Choose HZPT for reliable products and exceptional value.

nikon f3 motor drive coupling cover

Introduction to Nikon F3 Motor Drive Coupling Cover

1. Purpose

The Nikon F3 motor drive coupling cover is designed to protect and secure the motor drive coupling in place, ensuring smooth and efficient operation of the camera.

2. Compatibility

This coupling cover is specifically designed for use with the Nikon F3 camera, ensuring a perfect fit and reliable performance.

3. Material

Crafted from high-quality materials, the Nikon F3 motor drive coupling cover is durable and long-lasting, providing protection for the motor drive coupling.

4. Easy Installation

The coupling cover is easy to install, allowing for quick and hassle-free maintenance of the camera’s motor drive system.

5. Enhanced Performance

By using the Nikon F3 motor drive coupling cover, photographers can enjoy enhanced performance and functionality from their Nikon F3 camera, ensuring optimal results.

Introduction to Types of Drive Couplings

1. Gear Couplings

Gear couplings are known for their high torque capacity and ability to compensate for misalignment, making them ideal for heavy-duty applications.

2. Chain Couplings

Chain couplings are durable and reliable, capable of transmitting power efficiently in various industrial settings.

3. Grid Couplings

Grid couplings are designed to absorb shock and vibration, protecting connected equipment and ensuring smooth operation.

4. Disc Couplings

Disc couplings offer high torsional stiffness and misalignment capability, making them suitable for precision applications.

5. Jaw Couplings

Jaw couplings are easy to install and maintain, providing a cost-effective solution for moderate torque transmission.

Materials Used in Drive Couplings

1. Steel

Steel is commonly used in drive couplings for its strength and durability, making it ideal for heavy-duty applications.

2. Aluminum

Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight savings are essential.

3. Cast Iron

Cast iron is known for its high heat resistance and damping properties, making it a preferred material for industrial drive couplings.

4. Polyurethane

Polyurethane is a versatile material used in drive couplings for its flexibility and shock-absorbing capabilities, ensuring smooth operation.

5. Nylon

Nylon is a lightweight and wear-resistant material often used in drive couplings to reduce friction and extend the product’s lifespan.

Key Applications of Drive Couplings

– Automotive Industry: Drive couplings are used in vehicles to transmit power from the engine to the wheels, ensuring smooth acceleration and performance.

– Industrial Machinery: Drive couplings are essential components in various industrial machines, such as pumps, compressors, and conveyors, enabling efficient power transmission.

– Aerospace Sector: Drive couplings play a crucial role in aircraft systems, connecting different components and ensuring reliable operation in challenging environments.

– Renewable Energy: Drive couplings are used in wind turbines and solar panels to transfer power from the source to the generator, maximizing energy production.

– Marine Applications: Drive couplings are utilized in marine vessels to transmit power from the engine to the propeller, enabling propulsion and maneuverability.

Selection Criteria for Drive Couplings

– Torque Capacity: The selected drive coupling should have the appropriate torque capacity to meet the application’s power transmission requirements.

– Misalignment Tolerance: Drive couplings with high misalignment tolerance can compensate for shaft misalignment, reducing wear and tear on connected equipment.

– Operating Conditions: Consider the temperature, speed, and environment in which the drive coupling will operate to ensure optimal performance and longevity.

– Maintenance Requirements: Choose a drive coupling that is easy to install and maintain, minimizing downtime and reducing maintenance costs.

– Cost-Effectiveness: Evaluate the initial cost and long-term benefits of the drive coupling to ensure it offers value for money and meets budget constraints.

About HZPT

Basic information

Our company HZPT was established in 2006, is a manufacturer and exporter specializing in the design, development, and production of couplings. We have our own design and R&D team for 16 years. We can customize products according to the requirements of global customers. We have a comprehensive and complete quality inspection system from raw materials to finished products. All our products have CE and TUV certificates. Our company takes “customer satisfaction, our pursuit” as its purpose. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We look forward to establishing successful business relationships with new customers around the world in the near future.

Advantages

– We have 20 years of ODM and OEM experience

– 100% testing before shipment

– 24-hour service, any problem, we face it together

– Products use the best materials, and our OEM team regularly designs new products according to market demand

– Factory direct sales price for 4 years

– Customization, OEM, ODM packaging, and branding are all acceptable

Our philosophy is to survive by quality and develop by credibility, ensuring that our customers receive high-quality products at competitive prices. With a strong focus on customer satisfaction and product innovation, HZPT has become a trusted name in the industry.

motor drive shaft coupler

Introduction to Motor Drive Shaft Coupler

1. Functionality

The motor drive shaft coupler is an essential component that connects the motor shaft to the driven equipment, allowing for the transfer of power efficiently.

2. Durability

These couplers are designed to withstand heavy loads and high torque, ensuring long-lasting performance and reliability.

3. Flexibility

Motor drive shaft couplers are available in various sizes and configurations to accommodate different motor and equipment specifications, providing flexibility in application.

4. Alignment

Proper alignment of the motor drive shaft coupler is crucial for smooth operation and to prevent premature wear and damage to the equipment.

5. Maintenance

Regular inspection and maintenance of the motor drive shaft coupler are necessary to ensure optimal performance and to prevent breakdowns.

Introduction to Types of Drive Couplings

1. Mechanical Couplings

Mechanical couplings, such as gear couplings and grid couplings, provide high torque transmission and are suitable for heavy-duty applications.

2. Flexible Couplings

Flexible couplings, including elastomeric couplings and jaw couplings, absorb shock and vibration, reducing wear and tear on connected equipment.

3. Fluid Couplings

Fluid couplings, like hydraulic couplings and hydrodynamic couplings, transmit power through a fluid medium, offering smooth and controlled power transmission.

4. Magnetic Couplings

Magnetic couplings use magnetic fields to transfer torque without physical contact, ideal for applications requiring hermetic sealing and precise torque control.

5. Electrical Couplings

Electrical couplings, such as capacitive couplings and inductive couplings, transmit power wirelessly, eliminating the need for physical connections and allowing for flexible positioning.

Materials Used in Drive Couplings

1. Steel

Steel is commonly used in drive couplings for its high strength and durability, making it suitable for heavy-duty applications.

2. Aluminum

Aluminum drive couplings are lightweight and corrosion-resistant, ideal for applications where weight reduction is essential.

3. Cast Iron

Cast iron drive couplings offer excellent wear resistance and are suitable for applications with high shock loads and vibrations.

4. Polyurethane

Polyurethane couplings provide flexibility and vibration damping, reducing noise and extending the lifespan of connected equipment.

5. Composite Materials

Composite drive couplings combine different materials to achieve specific performance requirements, such as enhanced flexibility or corrosion resistance.

Key Applications of Drive Couplings

1. Industrial Machinery

2. Automotive Industry

3. Aerospace Applications

4. Marine Equipment

5. Renewable Energy Systems

Selection Criteria for Drive Couplings

1. Torque Capacity

2. Misalignment Tolerance

3. Speed and Temperature Range

4. Installation and Maintenance Requirements

5. Cost and Availability

About HZPT

Founded in 2006, HZPT is a leading manufacturer and exporter specializing in the design and production of high-quality couplings. With 16 years of experience, our company has a dedicated team for research and development, ensuring customized solutions for global customers. We prioritize customer satisfaction and offer CE and TUV certified products. Our commitment to quality, competitive pricing, and excellent service has made us a trusted partner for customers in Europe and the United States. Choose HZPT for reliable coupling solutions backed by years of industry expertise.

marine drive shaft coupling

Introduction to Marine Drive Shaft Coupling

1. Functionality

The marine drive shaft coupling is an essential component that connects the engine to the propeller shaft, allowing for the transfer of power from the engine to the propeller.

2. Durability

These couplings are designed to withstand harsh marine environments, ensuring long-lasting performance and reliability.

3. Alignment

Proper alignment of the drive shaft coupling is crucial to prevent vibration and ensure smooth operation of the marine propulsion system.

4. Corrosion Resistance

Marine drive shaft couplings are typically made from materials that are resistant to corrosion, such as stainless steel or bronze, to withstand exposure to saltwater.

5. Maintenance

Regular maintenance and inspection of the marine drive shaft coupling are necessary to ensure optimal performance and prevent potential issues.

Types of Drive Couplings

1. Flex Couplings

Flex couplings are designed to absorb shock, dampen vibration, and allow for misalignment between the engine and the propeller shaft.

2. Rigid Couplings

Rigid couplings are used when precise alignment is required between the engine and the propeller shaft, providing a direct and solid connection.

3. Gear Couplings

Gear couplings are capable of transmitting high torque and are often used in heavy-duty marine applications.

4. Fluid Couplings

Fluid couplings use hydraulic fluid to transmit power between the engine and the propeller shaft, providing smooth and gradual acceleration.

5. Magnetic Couplings

Magnetic couplings utilize magnetic fields to transfer torque, eliminating the need for physical contact between the engine and the propeller shaft.

Materials Used in Drive Couplings

1. Stainless Steel

Stainless steel is commonly used in drive couplings for its corrosion resistance and strength, making it ideal for marine applications.

2. Bronze

Bronze is another popular material choice for drive couplings due to its excellent wear resistance and compatibility with saltwater environments.

3. Aluminum

Aluminum drive couplings are lightweight and offer good thermal conductivity, making them suitable for certain marine propulsion systems.

4. Polyurethane

Polyurethane is used in flexible drive couplings for its elasticity, shock absorption properties, and resistance to oil and chemicals.

5. Carbon Steel

Carbon steel drive couplings are known for their high strength and durability, making them suitable for heavy-duty marine applications.

Key Applications of Drive Couplings

1. Marine Propulsion Systems

Drive couplings are essential components in marine propulsion systems, connecting the engine to the propeller shaft for efficient power transmission.

2. Industrial Machinery

Drive couplings are used in various industrial machinery applications, such as pumps, compressors, conveyors, and generators, to transmit power between rotating shafts.

3. Automotive Industry

Drive couplings are utilized in vehicles for connecting the engine to the transmission system, enabling the transfer of power and torque to the wheels.

4. Aerospace Applications

Drive couplings are employed in aerospace applications for connecting various mechanical components within aircraft and spacecraft systems.

5. Renewable Energy Systems

Drive couplings play a crucial role in renewable energy systems, such as wind turbines and solar power plants, for transferring power between different components.

Selection Criteria for Drive Couplings

1. Torque Capacity

When selecting a drive coupling, it is important to consider the torque capacity to ensure that it can handle the power requirements of the application.

2. Misalignment Tolerance

The drive coupling should have the ability to accommodate misalignment between the engine and driven shafts to prevent premature wear and vibration.

3. Operating Environment

Consider the operating environment, such as temperature, humidity, and exposure to chemicals, to choose a drive coupling material that can withstand these conditions.

4. Maintenance Requirements

Assess the maintenance needs of the drive coupling, such as lubrication intervals and inspection frequency, to ensure optimal performance and longevity.

5. Cost and Availability

Factor in the cost of the drive coupling and availability of spare parts to ensure cost-effectiveness and minimize downtime in case of replacement or repair.

About HZPT

Founded in 2006, HZPT is a leading manufacturer and exporter specializing in the design, development, and production of couplings. With a dedicated design and R&D team for 16 years, we offer customized solutions to meet the unique requirements of global customers. Our comprehensive quality inspection system ensures that all products meet the highest standards, backed by CE and TUV certifications. At HZPT, customer satisfaction is our top priority. Our commitment to quality, reliability, and competitive pricing has earned us a strong reputation among customers in Europe and the United States. We provide 24-hour service, OEM and ODM packaging options, and direct sales pricing to meet the diverse needs of our clients. Partner with HZPT for top-quality drive couplings and exceptional service.

magneto drive coupling

Introduction to Magneto Drive Coupling

- Function: The magneto drive coupling is designed to transmit power from the engine’s magneto to other components, allowing for the smooth operation of machinery.

- Design: This type of coupling is typically made of durable materials such as steel or aluminum, ensuring longevity and efficiency in power transmission.

- Installation: The magneto drive coupling is easy to install and requires minimal maintenance, making it a convenient choice for various applications.

- Compatibility: It is compatible with a wide range of machinery and equipment, providing versatility and flexibility in its usage.

- Benefits: The magneto drive coupling helps to reduce vibrations and noise, ensuring smooth and efficient power transmission for optimal performance.

Introduction to Types of Drive Couplings

1. Gear Couplings

Gear couplings are known for their high torque capacity and durability, making them suitable for heavy-duty applications in industries such as mining and construction.

2. Flexible Couplings

Flexible couplings are designed to absorb shock and vibration, protecting machinery from damage and ensuring smooth operation in various conditions.

3. Fluid Couplings

Fluid couplings use hydraulic power transmission to provide smooth, variable speed control, making them ideal for applications that require precise speed regulation.

4. Magnetic Couplings

Magnetic couplings eliminate the need for physical contact between components, reducing wear and tear while maintaining efficient power transmission in sensitive applications.

5. Elastomeric Couplings

Elastomeric couplings use rubber or plastic elements to dampen vibrations and misalignments, extending the lifespan of machinery and improving overall performance.

Materials Used in Drive Couplings

1. Steel

Steel is commonly used in drive couplings for its strength and durability, providing reliable power transmission in demanding applications.

2. Aluminum

Aluminum drive couplings offer lightweight and corrosion-resistant properties, making them suitable for applications that require efficient power transmission with minimal weight.

3. Cast Iron

Cast iron drive couplings are known for their high torque capacity and shock-absorbing capabilities, making them ideal for heavy-duty applications in various industries.

4. Polyurethane

Polyurethane drive couplings provide flexibility and damping properties, reducing vibrations and noise in machinery for smooth and efficient operation.

5. Composite Materials

Composite drive couplings combine different materials to optimize performance, offering a balance of strength, flexibility, and durability for reliable power transmission.

Key Applications of Drive Couplings

- Industrial Machinery

- Automotive Systems

- Agricultural Equipment

- Marine Propulsion Systems

- Aerospace Applications

Selection Criteria for Drive Couplings

- Power Transmission Requirements

- Operating Environment Conditions

- Maintenance and Serviceability

- Cost-Effectiveness and Longevity

- Compatibility with Existing Equipment

About HZPT

Our company, HZPT, has been a trusted manufacturer and exporter of couplings since 2006. With a dedicated design and R&D team, we specialize in producing high-quality drive couplings that meet global standards. Our commitment to customer satisfaction drives us to provide the best service and product quality, ensuring that our customers in Europe and the United States receive top-notch products at competitive prices. We take pride in our production strength and reliability, offering customization options, OEM services, and a comprehensive quality inspection system to guarantee the excellence of our products. Choose HZPT for exceptional drive couplings and experience the difference in performance and reliability.

magnaloy com

Introducing Magnaloy.com

1. Wide Range of Products

Magnaloy.com offers a diverse range of drive couplings, including radial elastic couplings, tire couplings, universal couplings, drum gear couplings, and more. These couplings cater to various needs in the machinery industry.

2. Customization Options

Customers can benefit from Magnaloy.com’s customization services, allowing them to tailor products to their specific requirements. The company’s design and R&D team ensures that all custom orders are met with precision.

3. Quality Assurance

With a comprehensive quality inspection system in place, Magnaloy.com guarantees the highest quality standards for its products. All couplings undergo rigorous testing to ensure durability and reliability.

4. Certification

Magnaloy.com products are CE and TUV certified, reassuring customers of their compliance with international quality and safety standards. This certification highlights the company’s commitment to delivering top-notch products.

5. Exceptional Customer Service

At Magnaloy.com, customer satisfaction is paramount. The company’s dedicated team provides 24-hour service, ensuring that any issues or concerns are promptly addressed. Customers can expect a seamless experience when dealing with Magnaloy.com.

Introduction to Types of Drive Couplings

Elastic Couplings

Elastic couplings, such as radial elastic couplings and plum blossom elastic couplings, provide flexibility and vibration damping, making them ideal for applications where misalignment and shock absorption are critical.

Gear Couplings

Drum gear couplings are designed for high torque transmission, offering excellent power transmission capabilities and reliability. They are commonly used in heavy-duty machinery and industrial applications.

Universal Couplings

Universal couplings allow for angular misalignment, providing flexibility in shaft connections. They are versatile and suitable for a wide range of machinery and equipment.

Rigid Couplings

Rigid couplings offer a solid connection between shafts, ensuring precise alignment and torque transmission. They are commonly used in applications where accuracy and rigidity are essential.

Diaphragm Couplings

Diaphragm couplings are known for their high torque capacity and torsional stiffness. They are ideal for applications requiring precise torque transmission and minimal backlash.

Materials Used in Drive Couplings

Steel

Steel is a common material used in drive couplings due to its strength and durability. It provides excellent torque transmission capabilities and is suitable for heavy-duty applications.

Aluminum

Aluminum is lightweight and corrosion-resistant, making it ideal for applications where weight reduction and resistance to environmental factors are important. It offers good thermal conductivity and is commonly used in various couplings.

Cast Iron

Cast iron is known for its high strength and wear resistance, making it suitable for demanding applications. It provides excellent damping properties and is often used in industrial couplings.

Polyurethane

Polyurethane is a versatile material that offers flexibility and vibration damping. It is commonly used in elastic couplings to absorb shocks and compensate for misalignment in shaft connections.

Stainless Steel

Stainless steel provides excellent corrosion resistance and durability, making it ideal for applications where hygiene and cleanliness are essential. It is commonly used in food processing and pharmaceutical industries.

Key Applications of Drive Couplings

1. Industrial Machinery: Drive couplings are widely used in various industrial machinery, such as pumps, compressors, and conveyors, to transmit power efficiently.

2. Automotive Sector: Drive couplings play a crucial role in automotive applications, connecting the engine to the transmission system for smooth power transfer.

3. Marine Industry: Couplings are essential in marine propulsion systems, ensuring reliable power transmission between the engine and propeller.

4. Aerospace Applications: Drive couplings are utilized in aerospace systems, providing precise torque transmission in aircraft engines and control mechanisms.

5. Renewable Energy: Couplings are integral components in wind turbines and solar power systems, enabling efficient power generation and transmission.

Selection Criteria for Drive Couplings

1. Torque Capacity: Select a coupling with sufficient torque capacity to handle the power requirements of the application.

2. Misalignment Tolerance: Consider the level of misalignment expected in the system and choose a coupling that can accommodate it without compromising performance.

3. Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals, to select a coupling material that can withstand these conditions.

4. Maintenance Requirements: Choose a coupling that is easy to install and maintain, reducing downtime and ensuring long-term reliability.

5. Cost-effectiveness: Balance performance requirements with budget constraints to find a coupling that offers the best value for your specific application.

About HZPT